Do you also have the feeling that January is almost over again? While we’re busy detailing our roadmaps, getting the next digital innovations up and running for our customers and preparing our appearance at the highly anticipated Drupa, we didn’t want to miss the opportunity to give you a taste of what’s to come in terms of digital this year.

Our mission remains unchanged: to lead the printing and packaging industry into the digital future. We do this by keeping our ear to the ground when it comes to identifying both market and technological trends. What will be our top 5 key topics in 2024?

1. Accessing & analysing production data

The IIoT capability of your production systems is the foundation for advanced data analytics. Data is the new gold – in 2024, there will be no way of getting around intelligent tools for production analysis.

2. Artificial intelligence in the pressroom

Everyone is still talking about AI. In 2023, a lot of attention was paid to the hype, and in 2024, smart digital solutions based on AI are set to find their way into production. At the same time, AI-based tools are an answer to the ongoing shortage of skilled labour.

3. Realising ESG goals

Sustainability, on the other hand, is no longer just a trendy topic, but an absolute necessity. Even when we talk about sustainability targets, reliable data and seamless, transparent monitoring of energy consumption and CO 2 emissions are essential – digitalisation and sustainability will go hand in hand in 2024.

4. Ensuring data security

Data, data, data – but how do we get the right data, how do we transfer it, how do we process and store it? Data-based digital solutions that access sensitive production data require the highest level of cybersecurity – another topic that is in the spotlight.

5. It’s Drupa time!

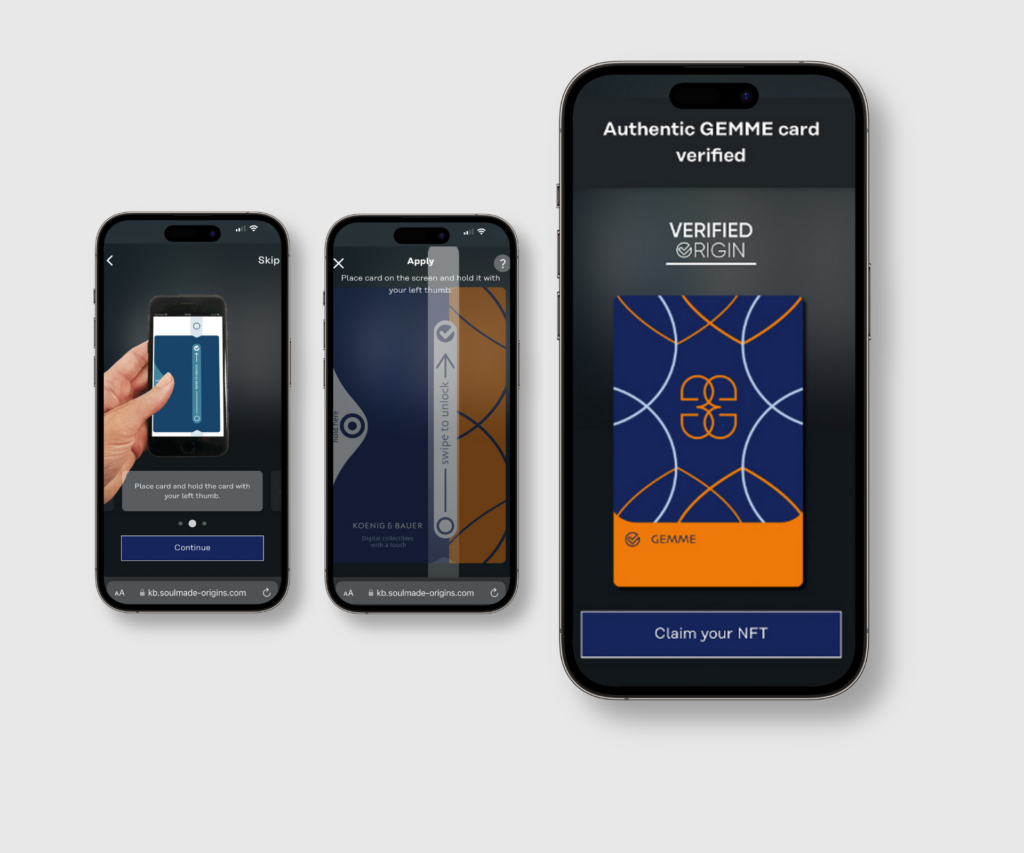

Last but not least: It’s finally Drupa time again! For the first time in many years, we are looking forward to the industry gathering in Düsseldorf. This is where outstanding printing technology is showcased alongside innovative digital solutions.

The focus is sharpened and we are already in the process of opening up new opportunities for our customers and the industry in these key areas in 2024. Are you ready? Then follow us and become part of our digital transformation journey.

#ReadyForTomorrow #DigitalTransformation #FutureofPrinting #FutureofPackaging #DigitalInnovation