- Digital Products

myKyana Portal

myKyana is the gateway to the digital world of Koenig & Bauer.

Kyana products

Discover the wide variety of possibilities offered by the Kyana product world.

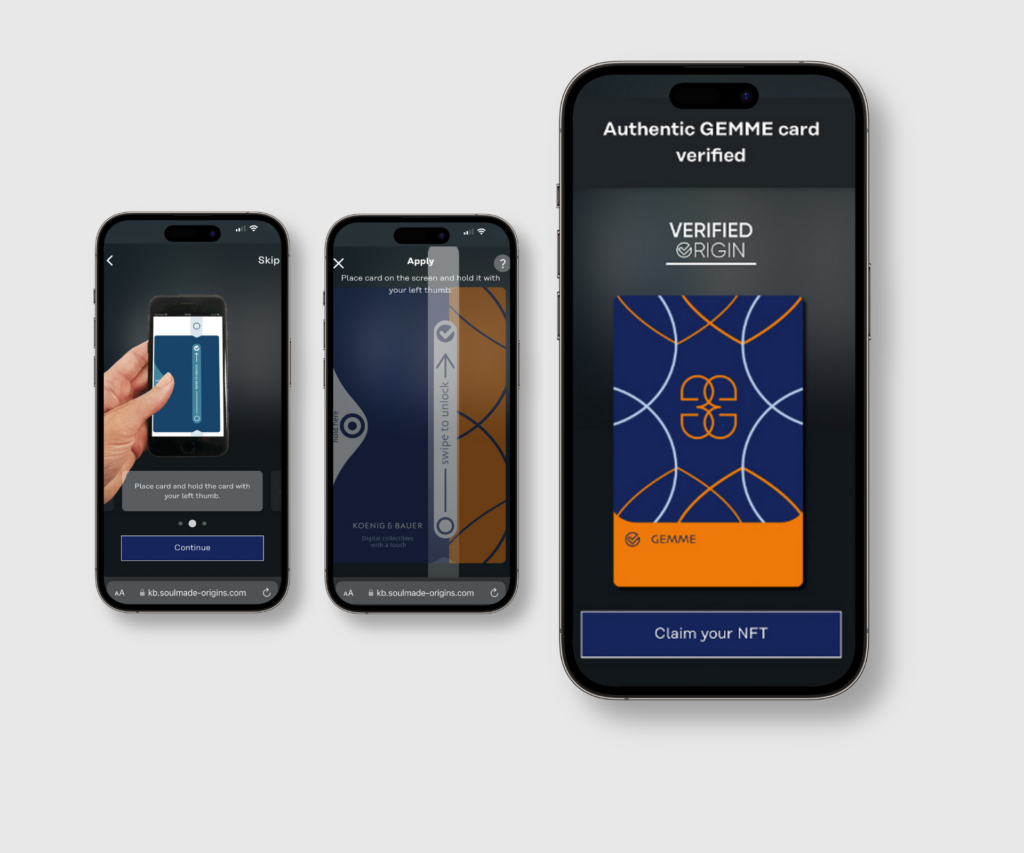

Other products

Discover more digital products from Koenig & Bauer and get started digitally.

- Koenig & Bauer Kyana

- News & Trends