In recent years, digital transformation has played a key role in society – including the business world. This transformation goes beyond the adoption of technology and affects the way we work, communicate and create value. Over the past few months, we have guided you through the ABCs of digitalisation on our channel to help you delve a little deeper into the often unfamiliar world of digital transformation. We have also benefited from this knowledge series, discovering interesting terms and learning new things. That is why we have compiled our top 10 digitalisation terms for you in this article.

Augmented reality (AR)

Augmented reality combines the real world with virtual objects. In this way, digital information merges with the user’s environment. The idea of augmented reality is to enrich the real world with digital information, opening up new possibilities in a variety of applications. In the world of printing and packaging, for example, remote maintenance can be improved by allowing technicians to look at the machine from a distance, which can reduce machine downtime. At the same time, AR can be used to make product presentations more detailed and training courses more interactive.

Cloud technology

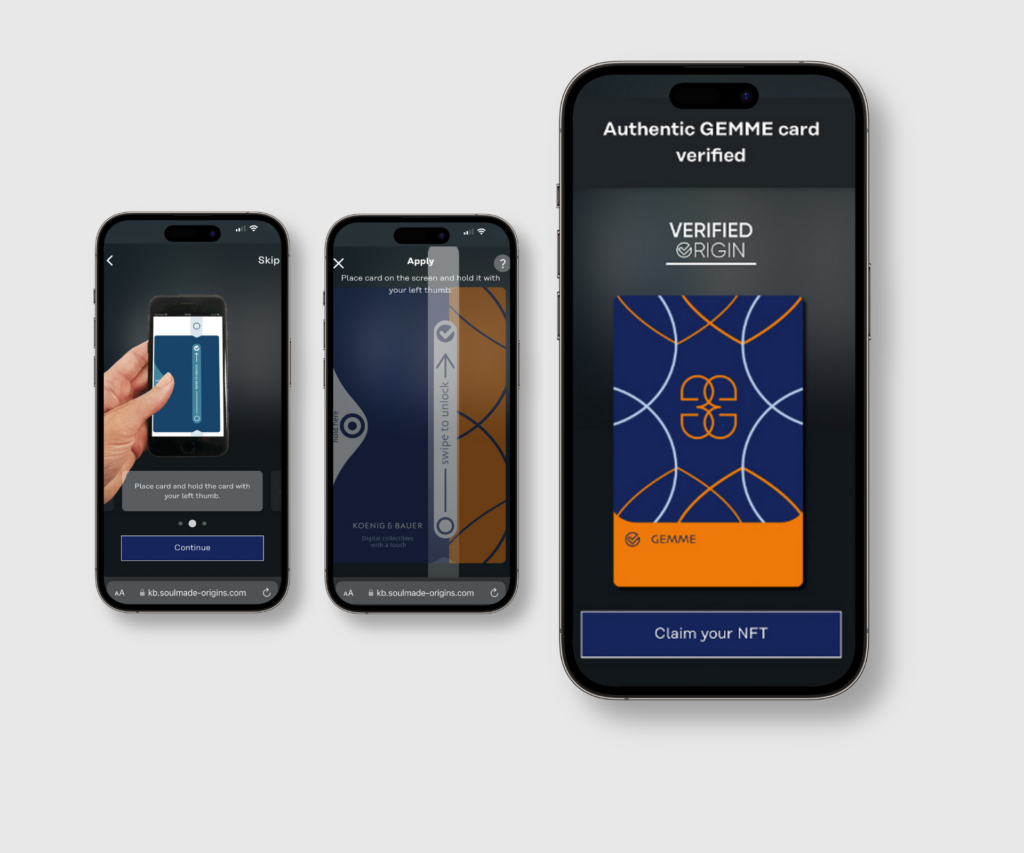

Cloud technology refers to the use of distributed servers hosted on the Internet to store, manage and process data, applications and services. The advantage is that companies do not need to maintain their own servers for large amounts of data – setting up their own data centres and IT security is much more costly. By using the latest cloud technology from a technology leader like Google Cloud, we at Koenig & Bauer are not only optimising the secure storage and processing of machine and job data, but also enabling collaboration across departments and business units with Google Workspace.

Digital Twin

A digital twin is a virtual representation of an object or system that covers its entire lifecycle, is updated with real-time data and uses simulation, machine learning and reasoning to support decision-making. The object under study is equipped with various sensors that cover key functional areas and provide data on different aspects of the physical object’s performance. Once this data is fed into the virtual model, it can be used to run simulations, investigate performance issues and develop potential improvements.

Gamification

Think frequent flyer programmes, loyalty points and frequent shopper points. These everyday examples showcase gamification, which describes the use of game-like mechanics in the real world to motivate individuals to achieve goals, improve performance or make purchases.

Gamification can unlock a range of benefits: By creating an immersive experience for users through the integration of gaming elements into processes and tasks, companies can improve customer and employee engagement, increase sales and maximise brand loyalty.

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) refers to the connection of industrial machinery with internet-enabled devices to increase efficiency and enable data-driven decision making. It uses sensors, networks and data analytics to optimise production processes and has the potential to transform industries through the seamless integration of physical and digital systems. Koenig & Bauer printing machines already have state-of-the-art IIoT integration. By equipping them with sensors, we receive real-time data on machine status, enable data-driven decisions and optimise maintenance.

Machine Learning (ML)

Machine learning is the art of teaching machines to recognise complex patterns in vast amounts of data and make intelligent decisions on their own. You can think of it as a computer program that works like the human brain – only faster. It uses algorithms to analyse data, learn from it and make predictions or take action without being specifically programmed to do so. For machine manufacturers like Koenig & Bauer, machine learning opens up a universe of new possibilities.

Predictive Maintenance

Predictive maintenance is one of these new possibilities. Proactive maintenance alerts based on real-time data and historical patterns enable production managers to make proactive decisions about upcoming maintenance activities. Potential sources of failure are predicted before downtime occurs. This approach optimises operational efficiency, improves predictability and enables better resource allocation.

Transformation

The terms digitalisation and transformation are inextricably linked. Digitalisation describes the process of converting analogue information or physical objects into a digital format. This process creates new opportunities and lays the foundation for the fundamental change for which the term digital transformation was coined. Digital transformation is an ongoing process, which is why it is often referred to as a ‘digital transformation journey’. It is about rethinking and reinventing the entire business model and processes of the company with the help of digital technologies in order to meet the changing demands and needs of customers.

Usability-Tests

Usability testing evaluates the usability of software products. Selected users are invited to test design concepts, prototypes or finished software products. Based on observations, feedback forms or personal interviews, developers receive quick and valuable feedback. The results serve as a compass for improving and developing software applications, ensuring that they meet the real needs and wants of their users.

Wireless Technology

Wireless technology is any communication or data transmission technology that works without physical wires or cables. In an increasingly connected world, wireless technology is often the glue that holds the physical world of machines and the digital world together. At Koenig & Bauer we use wireless technology to connect our printing machines seamlessly, creating end-to-end workflows and efficient production processes.

The digital journey does not end with this summary

Digitalisation is an ongoing process that enables us to develop innovative solutions and exceed our customers’ expectations. Look forward to more exciting developments.

Along with other exciting and informative insights into the world of Koenig & Bauer’s Digital Unit, you can find all 26 posts of the Digitalisation Alphabet on our channel.