Digital innovation and a pioneering mindset are crucial for companies that strive to always stay ahead of the curve and the competition. The traditional approach of closed innovation, where ideas are exclusively developed in-house has been abandoned by many organisations in favour of a more promising growth philosophy: open innovation.

Open innovation describes a way of creating innovations not behind closed doors, but in collaboration with external sources such as suppliers, start-ups, freelancers, scientific researchers, agencies or even competing companies. At Koenig & Bauer, open innovation is at the heart of our strategy, especially when it comes to digital products – here are five reasons why it works so well.

1. Access to external knowledge and talent

By opening up the innovation process, we are able to access a wide range of external knowledge and talent. Koenig & Bauer’s digital unit is currently attending a variety of networking events inside and outside of the industry. These spaces are precious to us, because connecting with other motivated innovative thinkers pose opportunities to co-create – and therefore provide us with the chance to find and leverage open innovation potential.

In 2019, Koenig & Bauer Coding co-created the voice-controlled AI solution Kyana, which focuses on predictive maintenance of our alphaJET coding series via a digital twin technology. This project came into being as an excellent example of a successful open innovation process: The collaboration with the Steinbeis Research Center of Design and Systems (Würzburg) won the prestigious “Löhnpreis“ for extraordinary projects and achievements in entrepreneurial knowledge and technology transfer.

2. Accelerating the innovation process

Just like in the Kyana project, open innovation, in many cases, enables companies to drive innovation even faster. Staying ahead of competitors is very rarely possible if these processes are driven without pushing the accelerator pedal. By working with external partners, valuable resources, skills and technologies can be combined and used in new, cooperative ways.

And no one needs to worry about not being able to find the right partners: Open innovation has become such a broad phenomenon, that there are platforms with the sole purpose of bringing together the right parties. They often see themselves as bridge-builders in the process of finding suitable collaboration partners for businesses, universities, researchers, even students. And selecting your partners carefully is half the battle: A bottleneck for an established corporation might not seem like a bottleneck to a research institute, or a start-up. This is true in terms of business strategy, product development, marketing activity, even HR management – and many other areas.

3. Saving costs and reduce risks

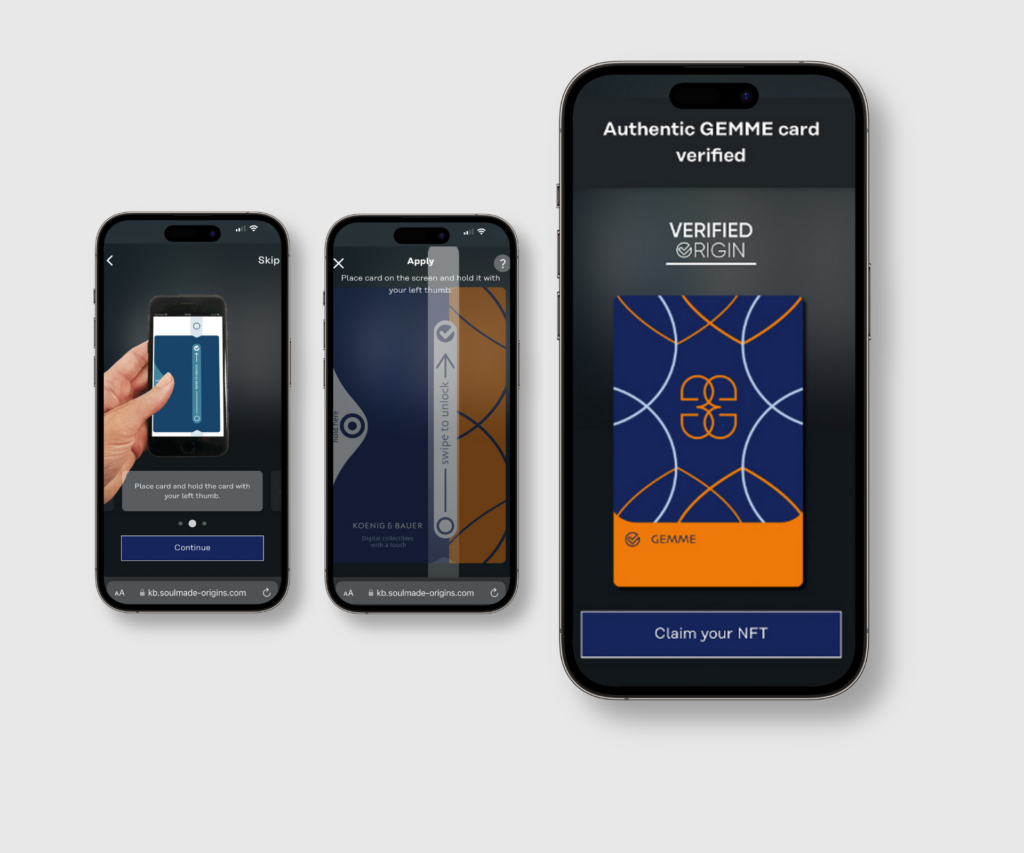

Instead of only investing in internal research and development, in open innovation companies can draw on existing knowledge and resources – for example by choosing state-of-the-art tech from external power-houses. Koenig & Bauer’s technology partnership with Google Cloud enabled us to build on a well-established reliable Cloud infrastructure instead of exclusively looking for solutions in a closed internal space.

4. Expanding market access and establishing new business opportunities

Never underestimate an opportunity to mingle – especially when it comes to open innovation. High-tech networks such as the Silicon Saxony Day 2023, where Koenig & Bauer recently spoke on becoming a data-driven tech company, offer amazing opportunities to learn of innovative solutions, and find inspiring people and organisations that strive to achieve similar goals. Attending these kind networking events with an open innovation mindset can open up new markets and business opportunities. Because finding the right external partners may broaden the access to new customer segments, geographic markets or even industries. Prospects are manifold in this area: collabs with external partners can lead to new products, services or even business models, that then of course have the potential to expand the business and, in the best case, generate new revenue streams.

5. Fostering creativity and engagement – inside and outside the company

Last but not least, open innovation fosters a culture of openness, creativity and engagement inside and outside the company. This is a point that is especially close to our hearts: we of course believe in employee enable- and empowerment.

To foster innovation and address the challenges in the print and packaging industry, we therefore organise internal innovation workshops involving various business units regularly. These workshops serve as platforms for brainstorming, ideation, and collaboration, where design thinking methods guide the sessions. We actively encourage participants to contribute their unique perspectives and ideas, resulting in inspiring outcomes. We are thrilled about the potential of these events and the collaborative efforts, as they enable us to leverage a diverse range of insights and develop innovative solutions for the industry’s most crucial issues.

If a staff body feels motivated and encouraged to contribute original ideas and actively participate in the innovation process, and this is met with external partners bringing in fresh perspectives and ideas – as we already had the privilege to witness at Koenig & Bauer – true magic can happen.