VisuEnergy X

All eyes on sustainability.

VisuEnergy X is the cutting-edge energy management system for a more climate-friendly printing and packaging industry.

Protect the environment and reduce your production costs with the ISO 50001-certified energy management system (EnMS) for energy-efficient printing and packaging production. Drive digitalisation & save sustainably now!

0% wasted ressources

100% transparency

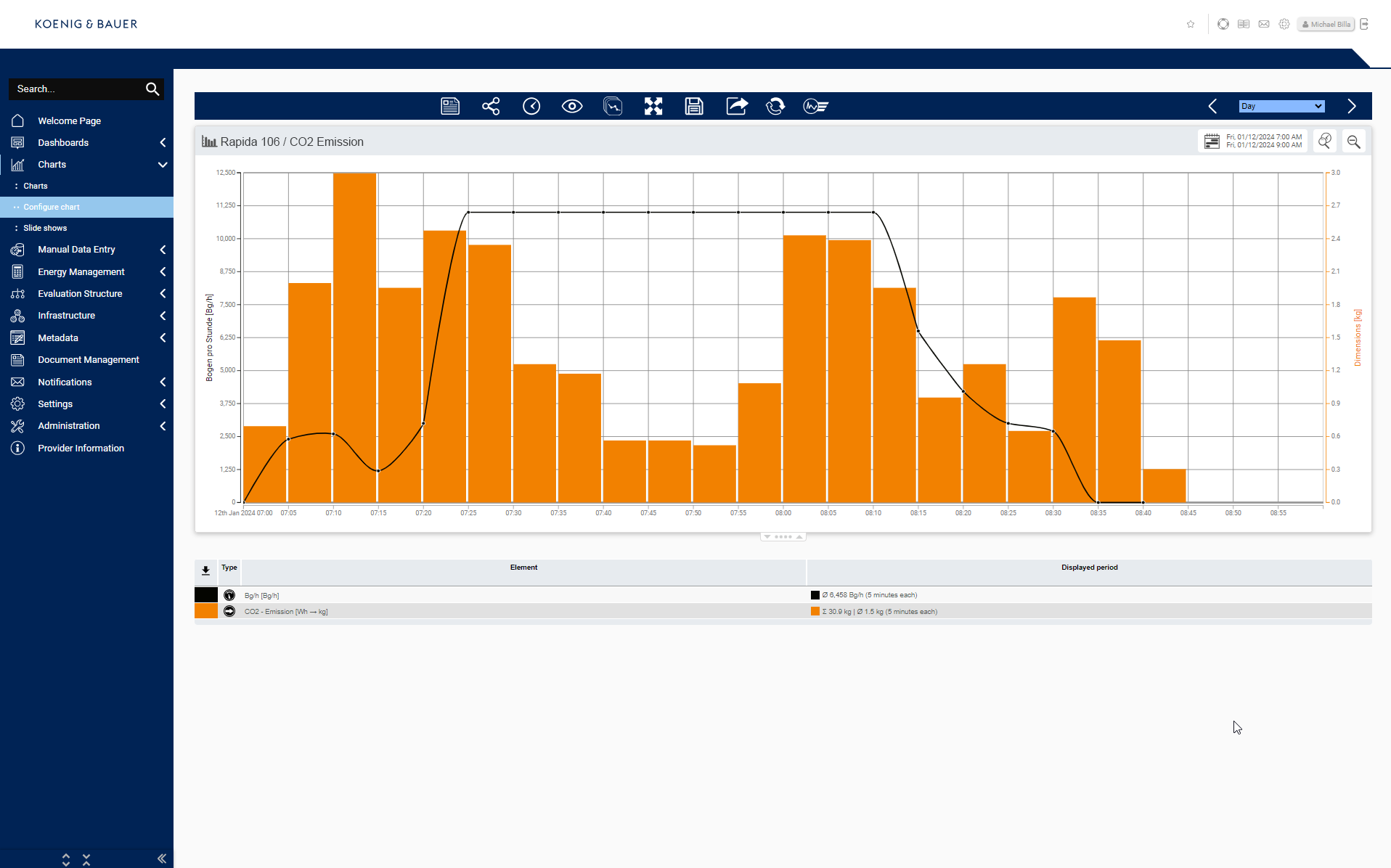

Capture data and reduce CO₂ emissions.

Why energy management?

Rising energy costs, sustainability targets and regulatory requirements are making energy a key competitive factor in the printing industry. On the road to improved energy efficiency, it is worth taking a detailed look at the energy requirements of your entire site – from production to building technology.

Today, digital technologies make it possible to record and visualise electricity consumption, CO₂ emissions and more. The seamless monitoring of this data is the basis for recognising long-term savings potential and initiating improvement measures.

Features

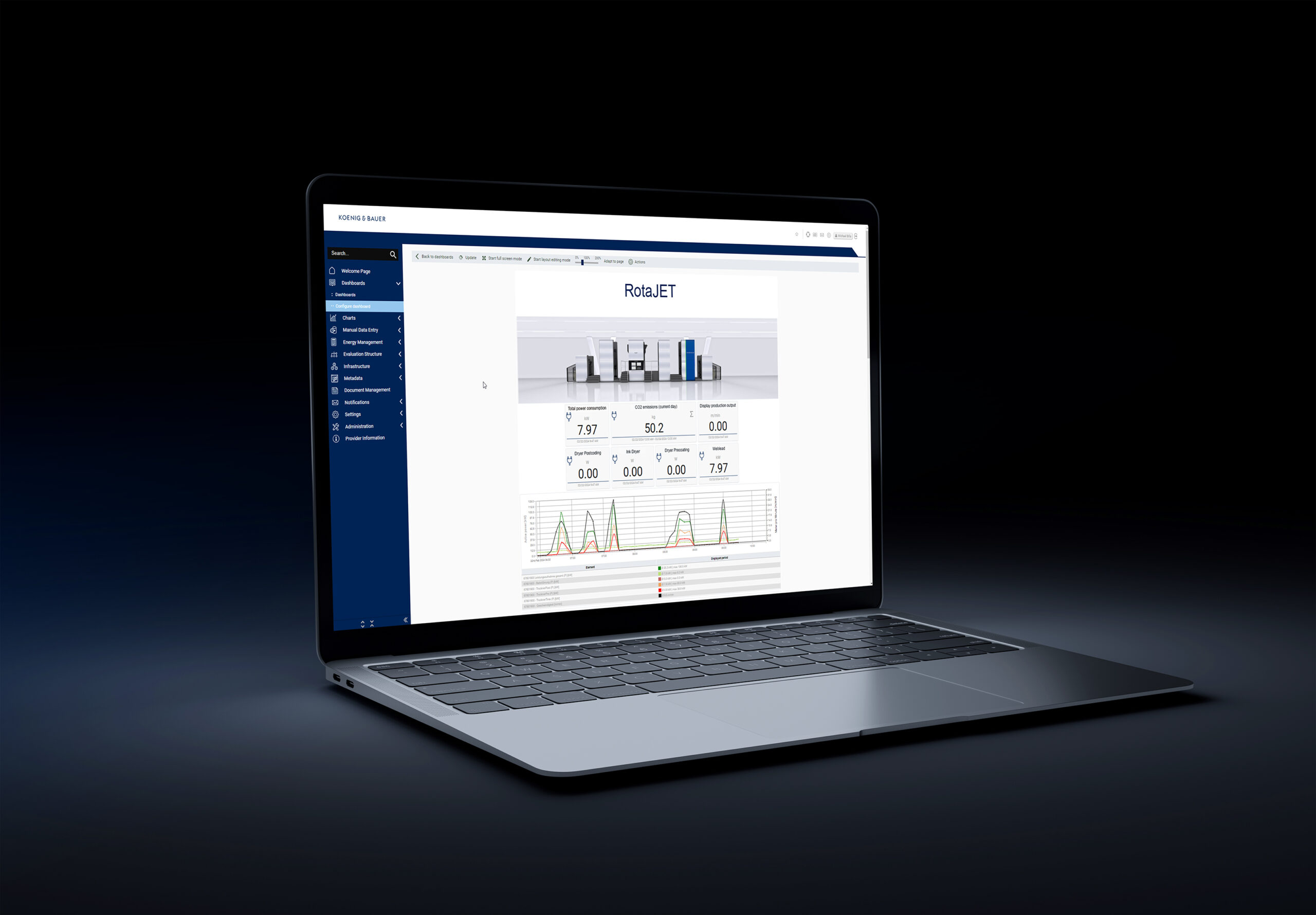

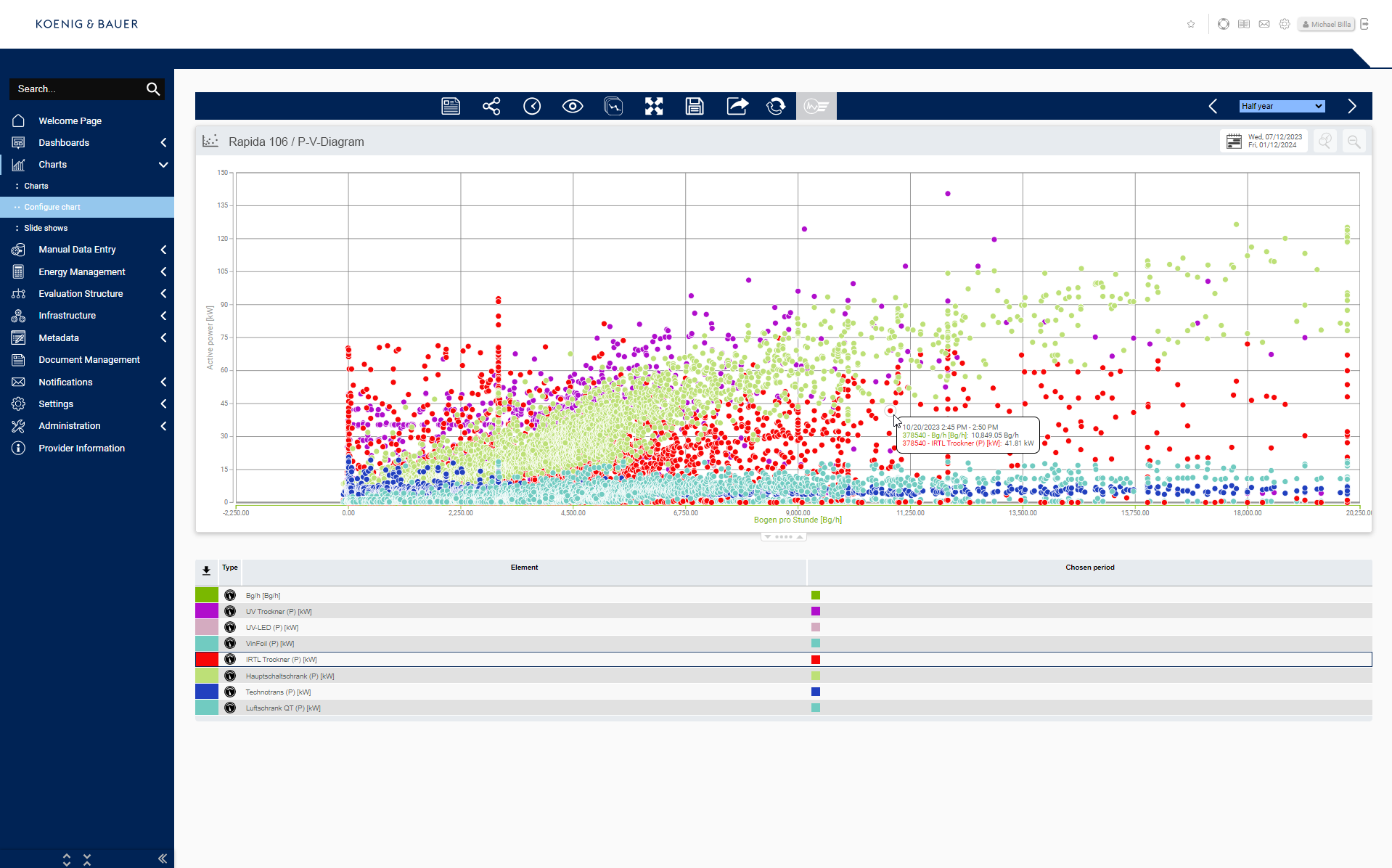

VisuEnergy X is the only solution on the market that enables the generation of industry-specific energy KPIs depending on the printing performance.

Capturing energy data

The EnMS enables automated reading of meters, data loggers and IoT sensors via all common APIs – scalable and expandable with additional sensors as required. Non-networked meters can be recorded manually using the corresponding mobile app (iOS & Android).

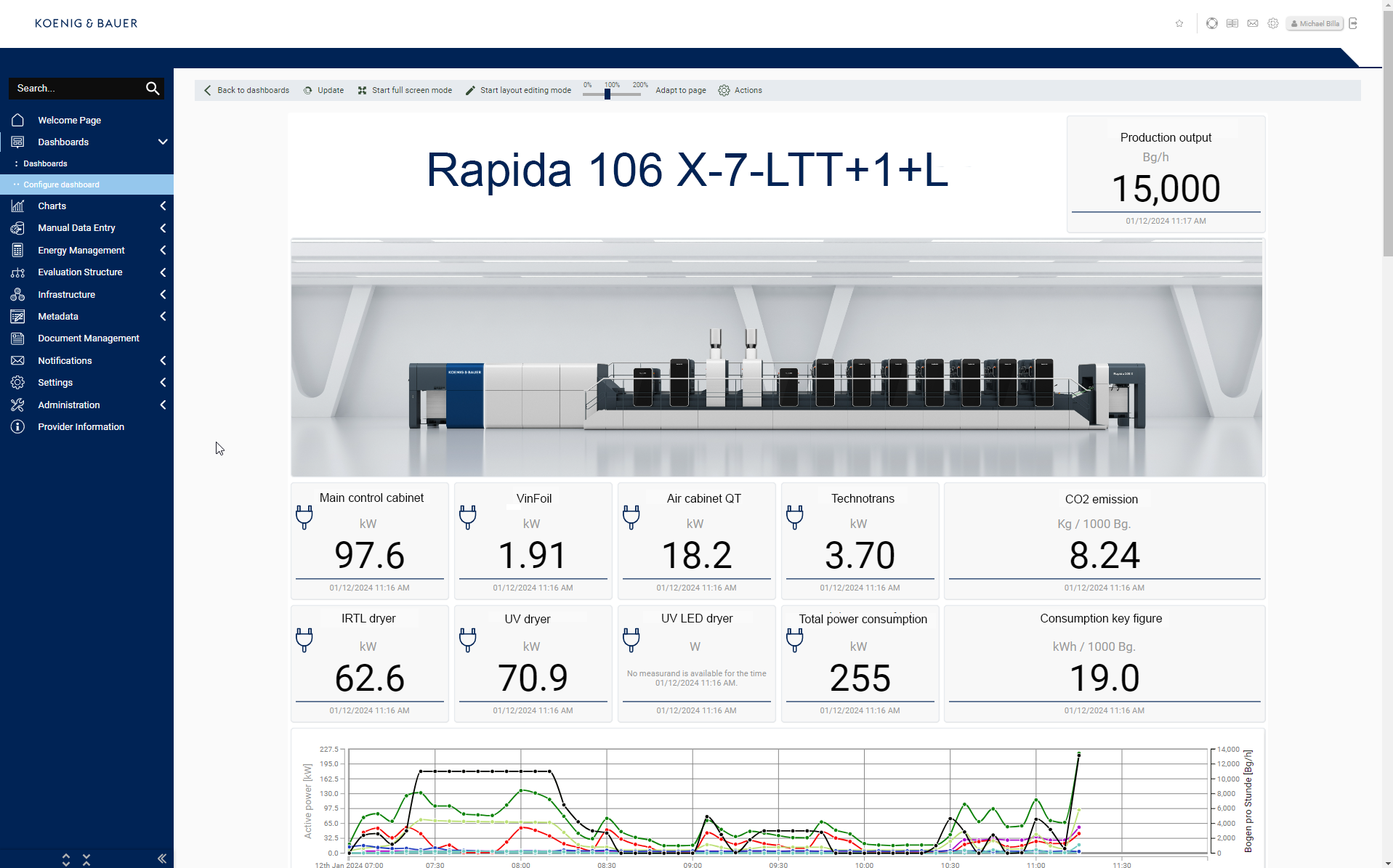

Visualisation and key figure generation

Energy data flows are graphically visualised using a variety of pre-designed chart types. A dashboard toolkit makes it easy to create customised analyses.

Comprehensive energy monitoring

The platform enables continuous monitoring and seamless documentation of energy data and thus provides the basis for a successful energy management. A look at consumption patterns and specific consumers reveals where the greatest savings potentials are located.

Reports and records

Extensive reporting and export options simplify the provision of evidence to customers, end users and regulators. The EnMS archives measurement data reliably and securely so that it can be retrieved retrospectively at any time.

Your benefits

Holistic solution

Comprehensive solution portfolio of software, measuring devices and consultancy

One-stop solution from your trusted machine supplier

Flexible subscription

Subscription model including hosting, support and updates

Unlimited users and connected sites, as well as easy extension of the measurement concept

Secure cloud software

Cloud solution with the highest security standards for your energy data

Data centre in Germany certified according to DIN ISO/IEC 27001

Industry specific KPIs

Software optimised specifically for print and packaging manufacturers

Industry-specific KPIs based on production output

Compatibility

Browser interface, supported by all common web browsers

Compatibility with all energy consumers, including older machine models and third-party machinery

Intuitive user interface

Easy-to-use dashboard builder for customised analysis

Continuous support during initial configuration and user training