Packaging becomes an experience: consumer expectations are redefining the brand world and revolutionising the role of the printing industry. The demand for personalisation and immediate interaction makes packaging a dynamic element of the customer journey. This development is forcing brand owners and their printing partners to fundamentally rethink their collaboration and integrate digital value-added services into physical packaging.

The demand for personalisation and immediate interaction is turning packaging into a dynamic element of the customer journey. This development is forcing brand owners and their print partners to completely rethink their collaboration and to integrate digital value-added services into physical packaging. To meet this dynamic and bridge the growing gap between physical packaging and the digital world, Koenig & Bauer has developed a revolutionary product: AURAVEO.

You can find out how this product works and what advantages it offers in this article.

The Digital Bridge: What is AURAVEO?

AURAVEO, the latest digital product from Koenig & Bauer Kyana, is a Digital Experience Platform that closes the gap between analogue packaging and the digital world. Every piece of packaging becomes an interactive communication channel, establishing a direct connection between a brand and its customers – a completely new marketing channel for brand owners!

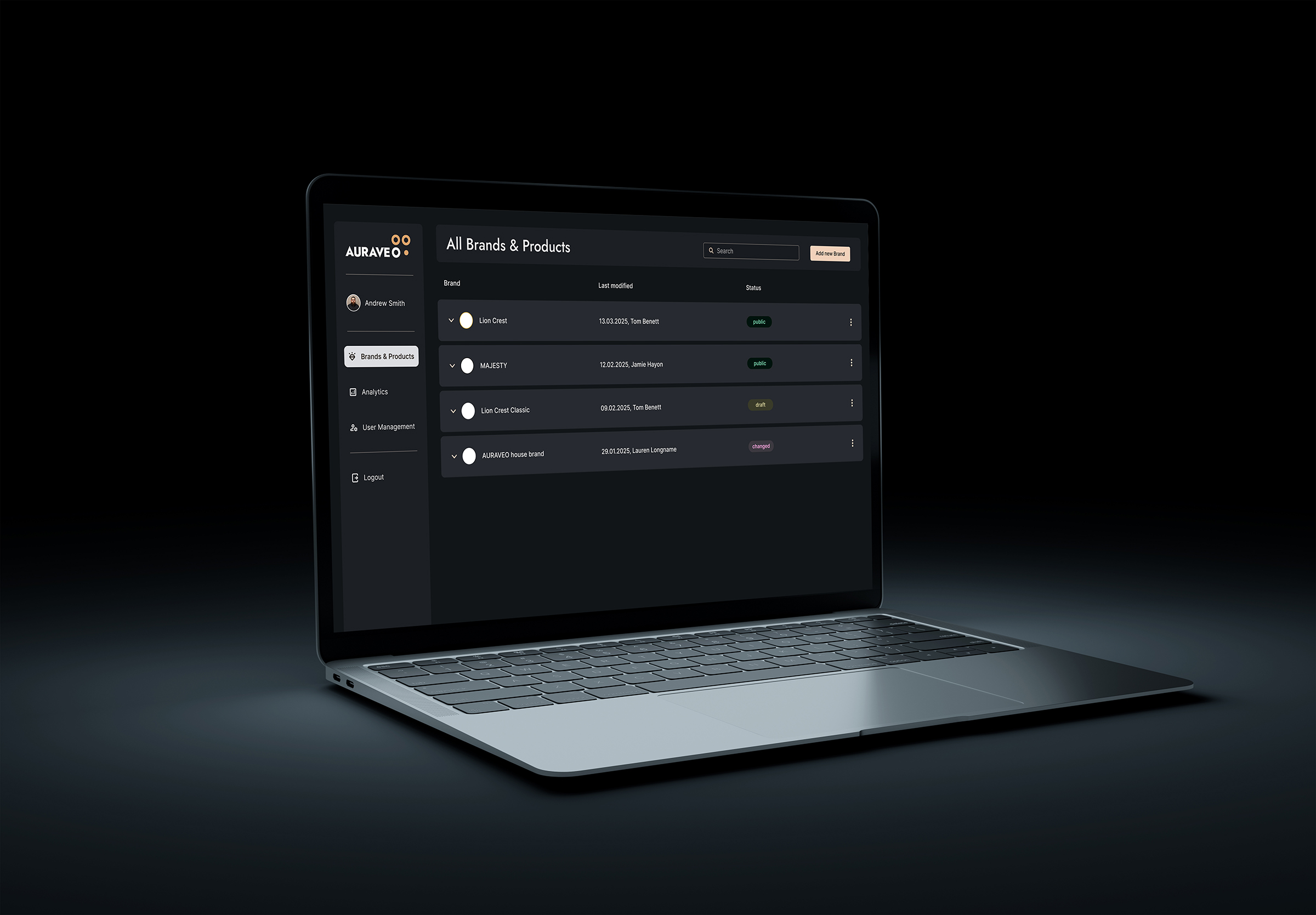

With AURAVEO, Koenig & Bauer can transform static packaging information into dynamic brand experiences that are visible directly on the product packaging. These can be enriched with innovative technologies such as Augmented Reality and Artificial Intelligence.

Experiential Packaging Design: How AURAVEO Works

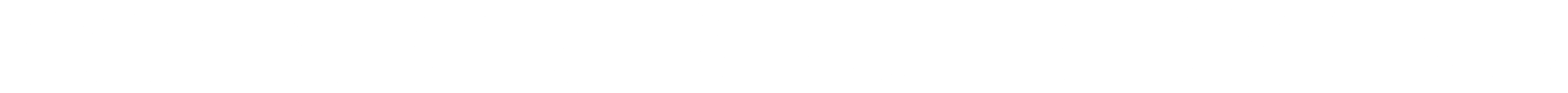

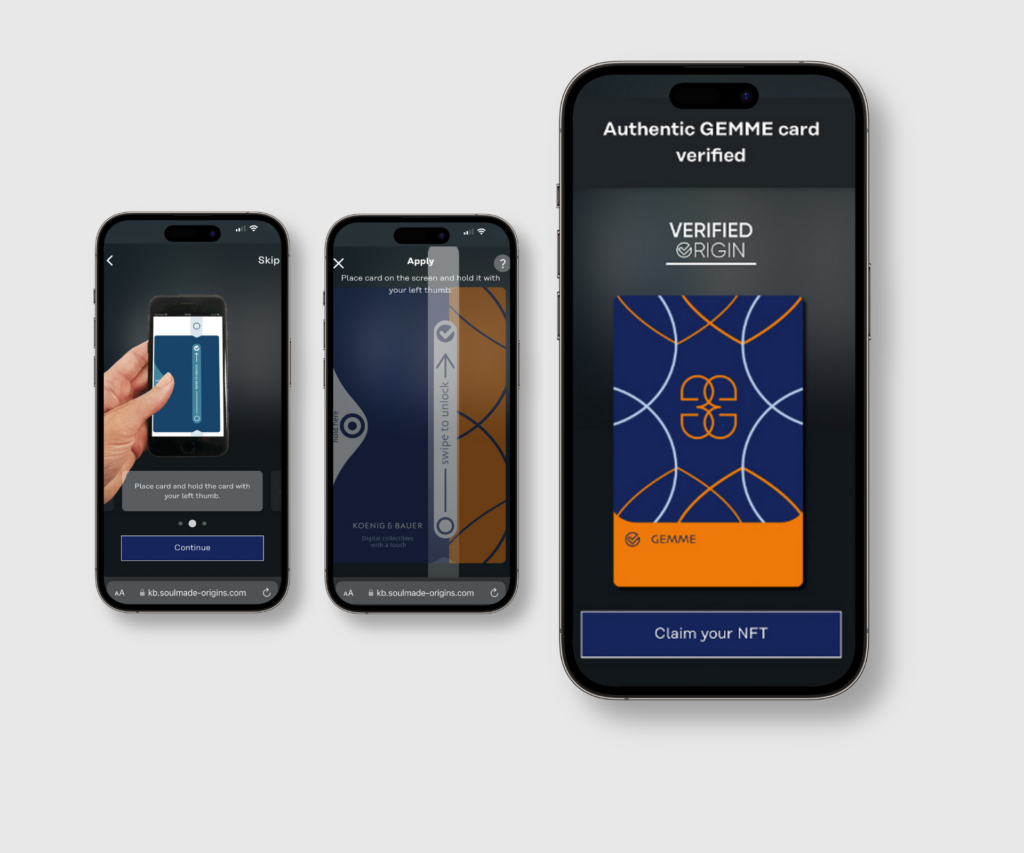

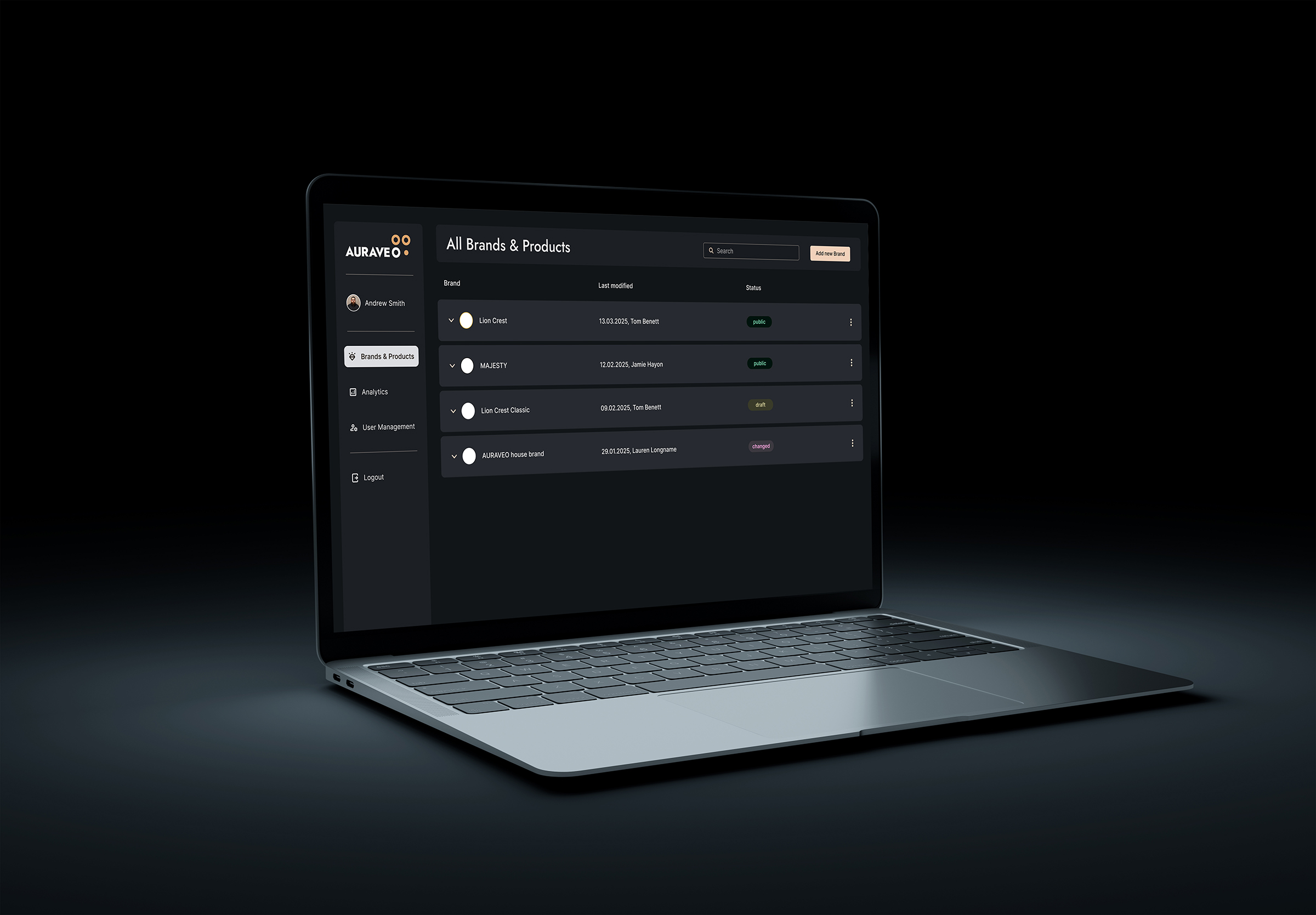

AURAVEO consists of a Brand Portal, our Digital Experience Platform, where brand owners can store their digital content that will be displayed when the product packaging is scanned. This content can be, for example, websites, videos, augmented content, and immersive 3D objects, which brand owners can use for their customer experience.

The possibilities are endless: seasonal offers, competitions, limited editions, and much more – and brand owners can easily change this content within seconds in the AURAVEO Brand Portal and thereby make it visible on the product packaging.

This technology allows brands to keep control over their content at all times, even if the products are already on the sales shelf. The goal is to make communication more personal and relatable. We provide brands with the tools they need to meet consumers’ increasing expectations for personalised and interactive experiences.

Demonstrating innovative strength

AURAVEO’s innovative strength has already been recognised with several awards. The digital experience platform won the Start-up Valley Award for ‘Start-up of the Year in Digital Marketing’ at the launch of the product at DMEXCO. At the same time, the company was named ‘Company to watch’ in connection with AURAVEO at the Digital Packaging Summit.

Data, Added Value, and the Future

Every scan with AURAVEO provides valuable information about consumers and their interactions with the packaging. Brands thus gain detailed insights into their customers’ preferences, purchasing behaviour, and usage patterns. This precise data makes it possible to segment campaigns specifically and optimise marketing measures.

The result: a measurable added value that strengthens customer loyalty and significantly increases the Return on Investment (ROI) of marketing activities.

AURAVEO is far more than just a bridge between the analogue and the digital world. It is a powerful tool that gives brand owners back control over their communication in real time. This allows them to not only meet but exceed consumers’ increasing expectations for personalised and interactive experiences.

Would you like to find out how your packaging can become a dynamic brand experience? Contact us for more information on AURAVEO.