Increasing costs and stricter sustainability regulations are making structured energy management (EnMS) increasingly important. For this reason, since last year, VisuEnergy X, Koenig & Bauer Kyana’s energy management system, has been integrated into the Koenig & Bauer Industrial plants in Würzburg and Radebeul to record and visualise energy consumption in production. This article explains how the plant integration has progressed so far, what insights have been gained, and what results have been achieved.

EU directive also affects Koenig & Bauer: How green production is becoming the new norm

In November 2023, the new EU Directive 2012/27/EU came into force, obliging companies to regularly monitor their energy consumption and take measures to reduce energy waste. These requirements have been transposed into national law through the Energy Efficiency Act and are particularly relevant for companies with high energy consumption, as they are required to implement an energy management system. This has far-reaching implications for production processes at Koenig & Bauer Industrial, as it demands precise recording and sustainable management of energy data. For this reason, the company started using Koenig & Bauer’s in-house energy management system, VisuEnergy X, to assess energy usage at its Würzburg and Radebeul plants last year.

VisuEnergy X is a holistic energy management system specifically developed for the printing and packaging industry. As a complete solution, it can record all energy consumers via measurement sensors – from lighting and coffee machines in the staff kitchen to the entire machine park. By precisely recording consumption data, the programme helps identify major consumers, known as ‘Significant Energy Users (SEU)’, as well as potential saving. This makes it easier for companies to meet legal requirements in the long run. However, fulfilling official guidelines is not the only objective. VisuEnergy X makes it possible to design production more sustainably and resource-efficiently, which is associated with direct cost savings. Through the accurate recording of energy consumption, it is possible to break down and record the carbon footprint of specific production processes down to individual orders.

Plant integration: Practical insights and useful observations

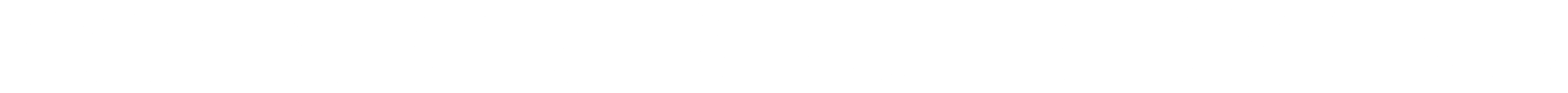

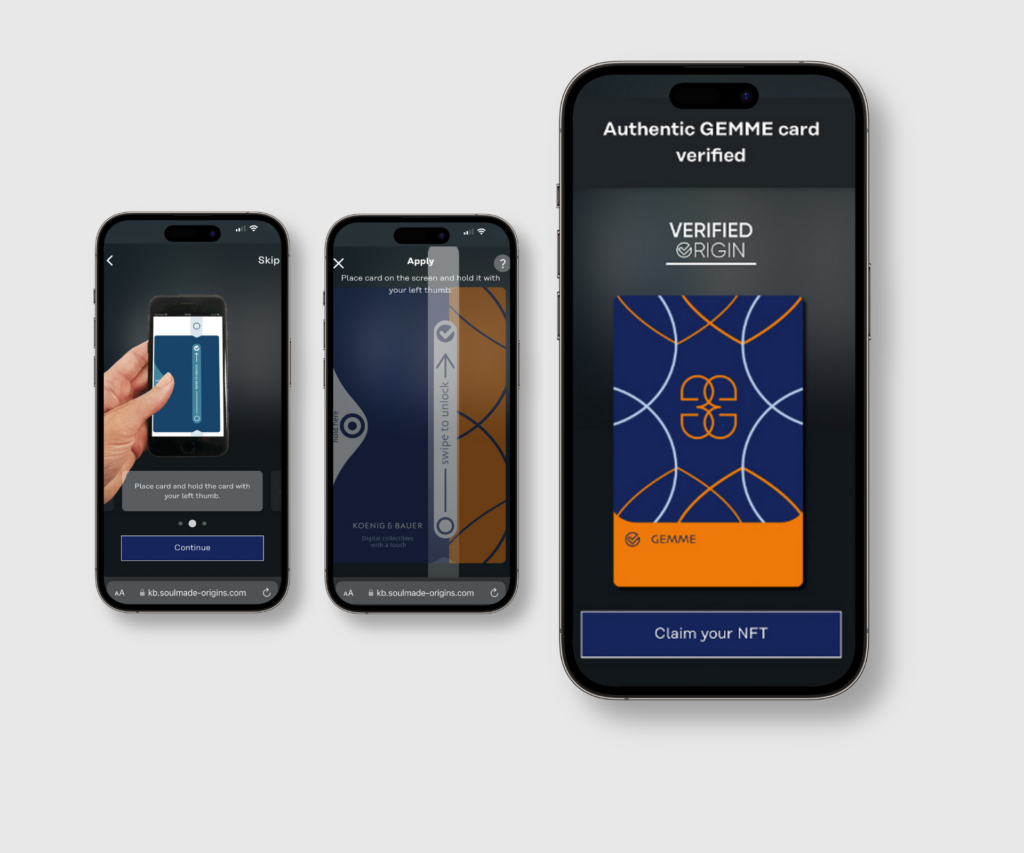

A central step in integrating VisuEnergy X into Koenig & Bauer Industrial’s plants was establishing clear structures. Various buildings, machines, and energy consumers were set up in the energy management system and structurally subdivided correctly, depending on their location or consumer group. This well-thought-out structure enables Koenig & Bauer to calculate energy consumption for the entire group in the future and seamlessly integrate new consumer groups into this existing structure. During the integration of measuring devices into VisuEnergy X, existing meters were successfully connected. Thanks to a developed interface, data previously recorded only manually are now automatically captured, enabling effective analysis and KPI generation. The measurement sensors already integrated into the machines in large-parts manufacturing were also successfully automated. It is particularly noteworthy that the foundry has been successfully operating with an EnMS since 2015. Data from this system was also integrated into VisuEnergy X to obtain a complete picture of the company’s energy consumption.

Scalable and future-proof: Step by step towards holistic energy management

Not every project needs to be fully implemented from the outset – especially in energy management, gradual progress is possible and often sensible. The integration of VisuEnergy X is not yet complete, on the contrary, it is entering its next phase. In the future, heating, air conditioning, and compressed air systems, among others, are also to be fully integrated into VisuEnergy X. Currently, their consumption data are still recorded in separate systems, meaning they have to be manually entered into the energy management system. The goal is automatic data capture. Furthermore, additional machine tools are on the list: the aim here is to break down energy consumption to individual production orders – for example, for the manufacture of an ink fountain or a sub-base box. Since electricity and natural gas consumption are already being recorded, other media such as district heating or hydrogen are to be added in the medium term.

The path is clear: step by step, a holistic energy management system is being created – flexible, scalable, and future-proof.

Challenges overcome and benefits recognised

VisuEnergy X enables Koenig & Bauer Industrial to compare ‘apples with apples and pears with pears’. By defining consumer groups, such as series machines operating in a three-shift system, the main consumption has been clearly identified. VisuEnergy X particularly impresses with its high flexibility, which allows for effortless structuring of consumer groups, seamless integration of manual meters, and reliable forecasting.

The implementation of VisuEnergy X significantly optimises energy management. The new VALERI feature, which allows for profitability calculations according to DIN EN 17463, was particularly well received. Koenig & Bauer Industrial’s energy management system has now been successfully certified according to DIN EN ISO 50001.

Conclusion:

Energy management is no longer just a ‘nice to have’ but a real competitive factor. VisuEnergy X is not only the central system for Koenig & Bauer but also the first complete solution for the entire printing and packaging industry. With the successful integration at Koenig & Bauer Industrial, we demonstrate that our product is not only technically convincing but also successfully implemented in our own plants.

Find out more about VisuEnergy X and other digital solutions here on our website.

Bleiben Sie auf dem Laufenden über die Koenig & Bauer Industrial auf LinkedIn ! Und folgen Sie uns für weitere Updates und Einblicke auf LinkedIn hier.