LogoTronic

Your True Productivity Companion.

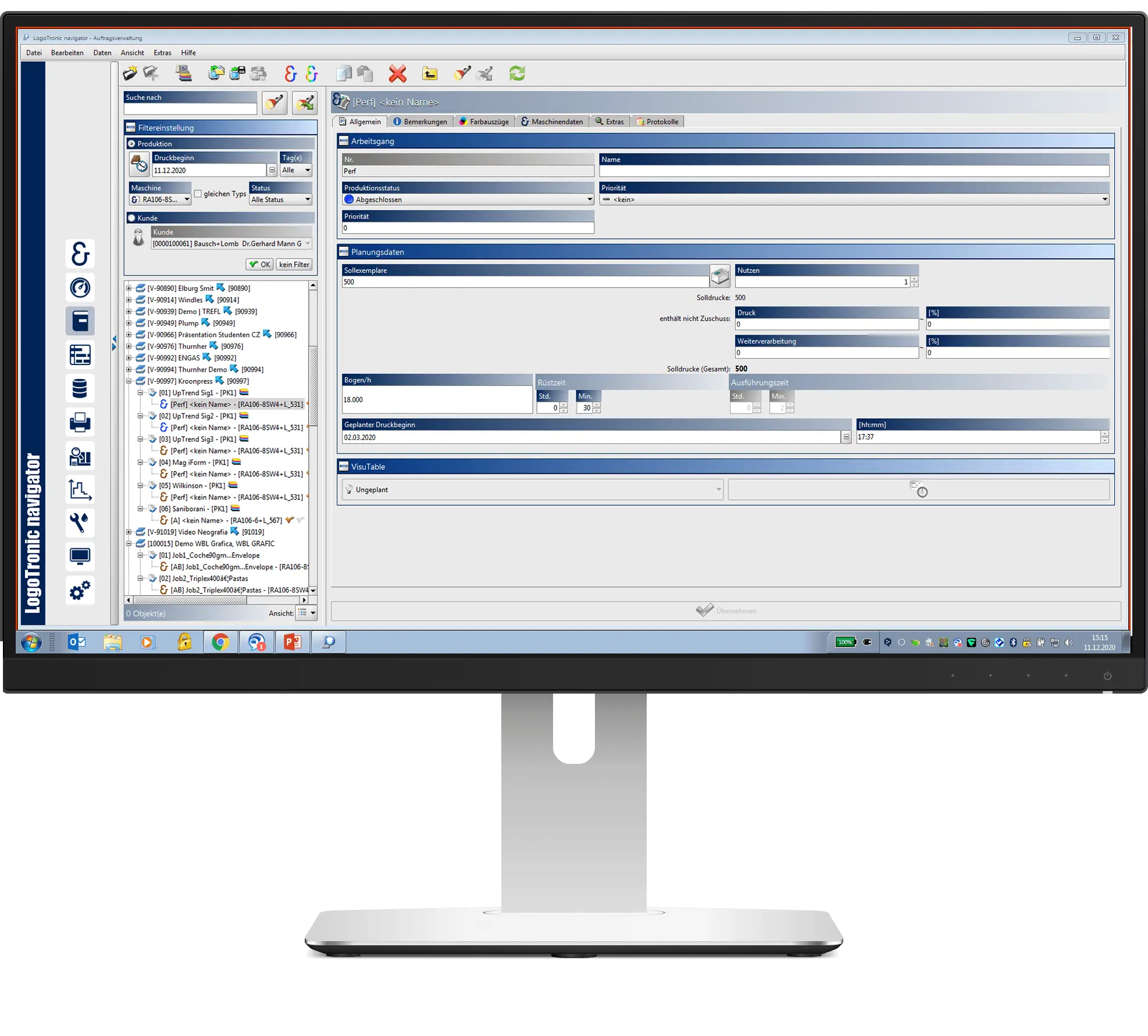

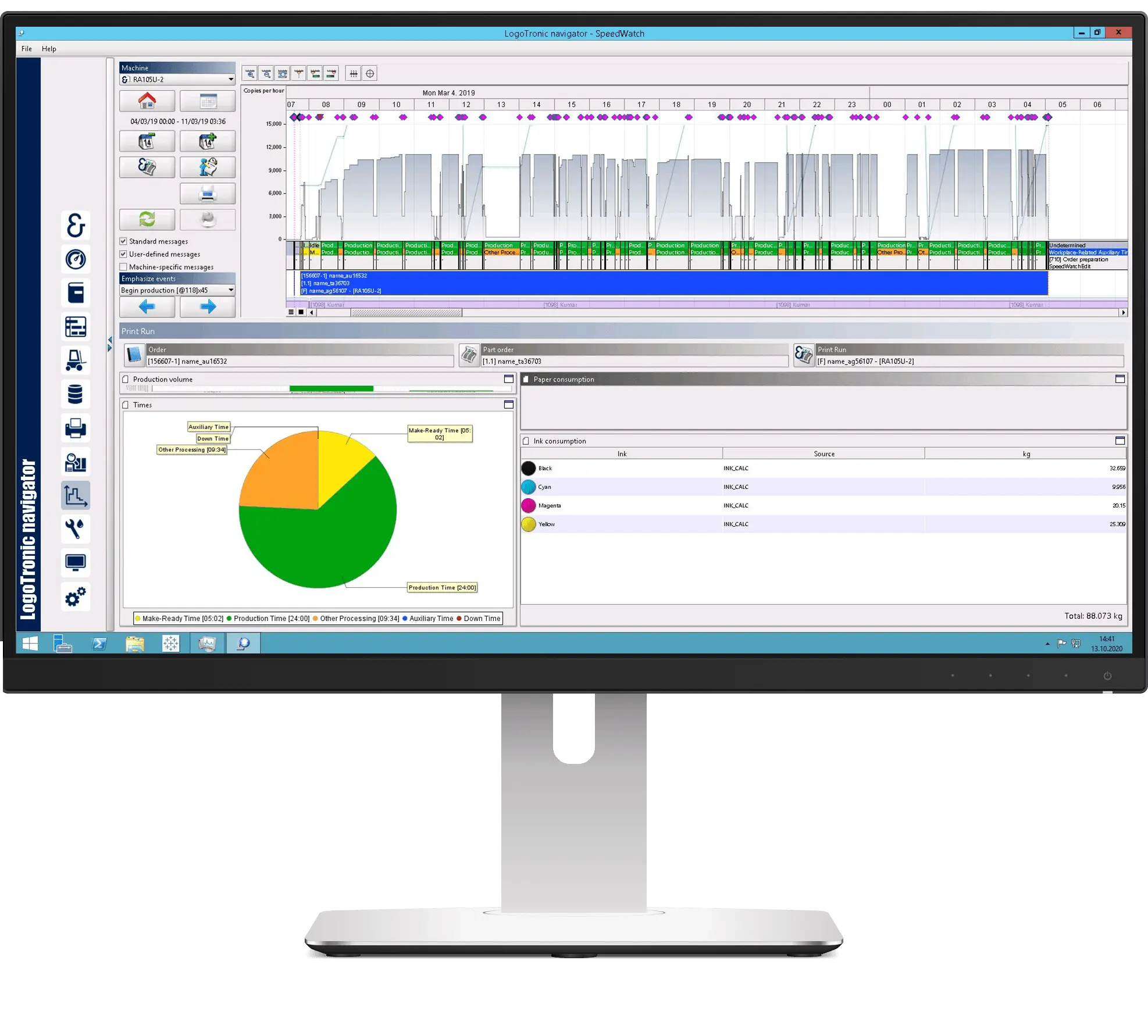

LogoTronic is the answer to the complexities and challenges of modern print production. It’s your intelligent Manufacturing Execution System, designed to help you maximise productivity and gain full control over your operations. From planning and machine pre-setting to reporting, it’s flexible, scalable, and always connected. Maximise your productivity with just one click.

Little effort

100% transparency in production

Why should you choose LogoTronic?

Modern print production faces the significant challenge of handling increasingly complex orders in shorter timeframes. LogoTronic supports you at every stage – from order creation and machine pre-settings to real-time tracking and reporting. This allows you to create well-founded decision-making bases for pre- and post-calculations, ensuring maximum transparency and planning quality in your production.

Features

Machine Pre-settings

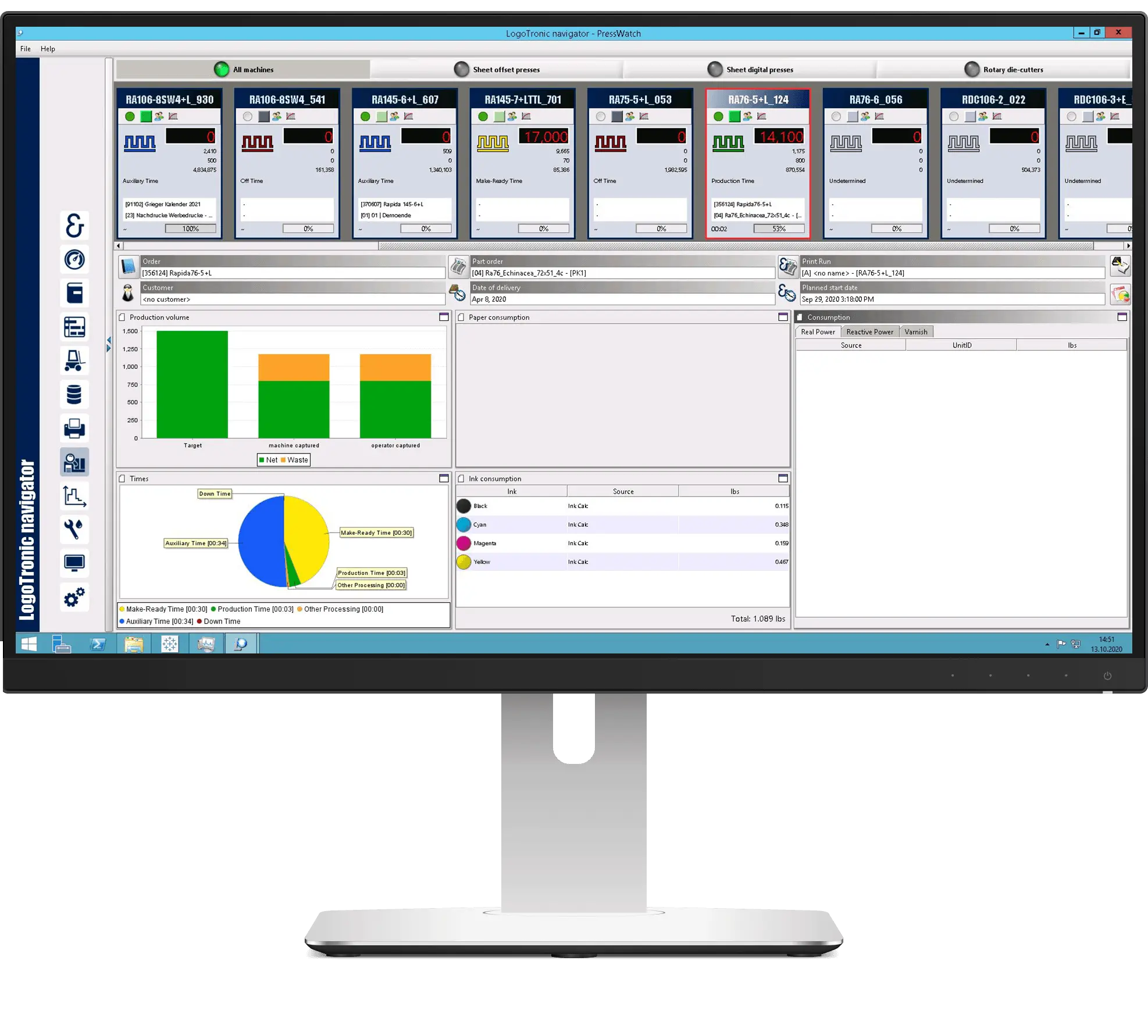

Automatic job creation, ink zone pre-settings, and storage for CIP3 PPF and CIP4 JDF data for reduced set-up times.

DataMatrix Select

Revolutionary automation with QR code-based plate identification to minimise manual interventions and the associated increased potential for errors.

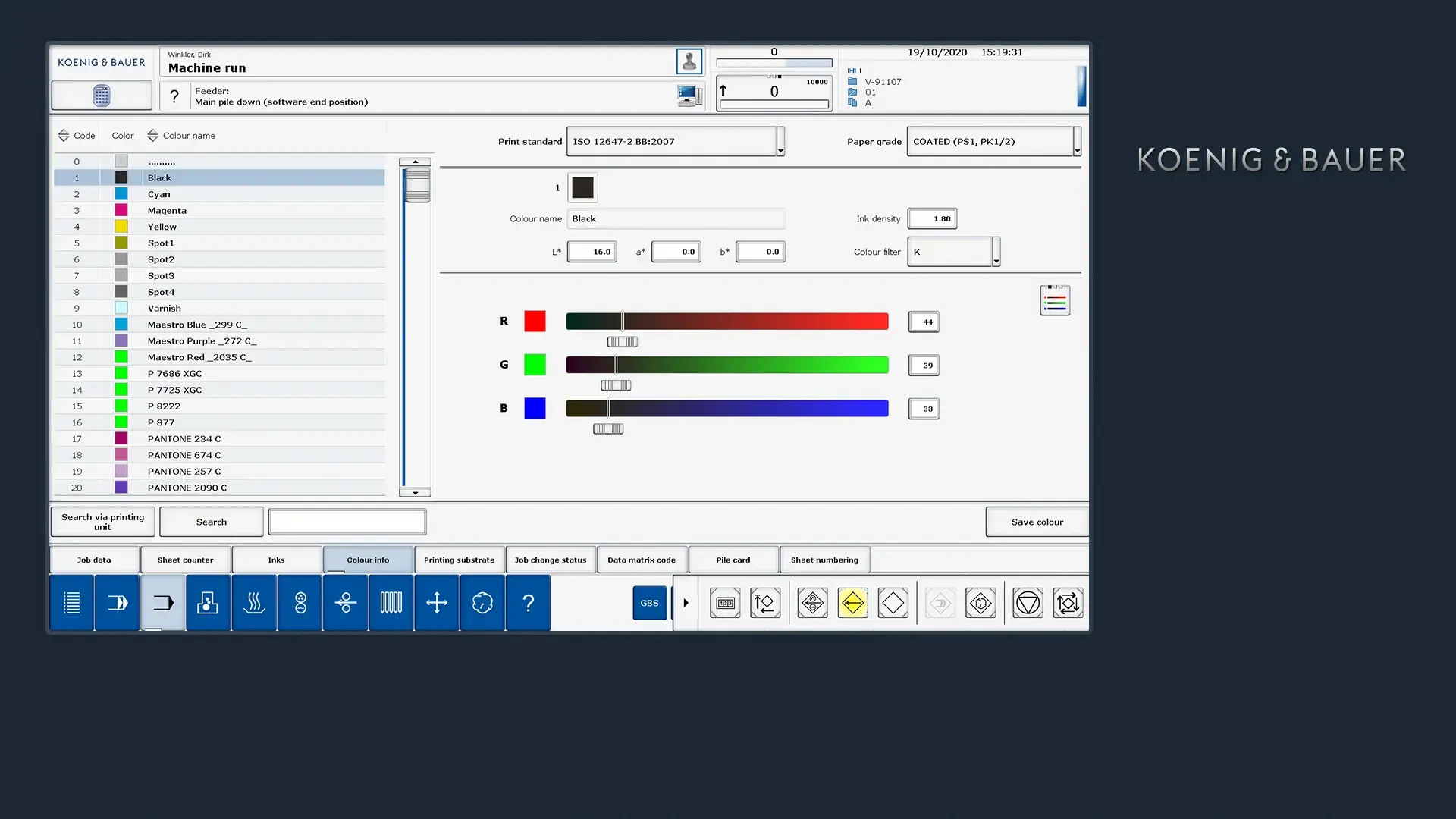

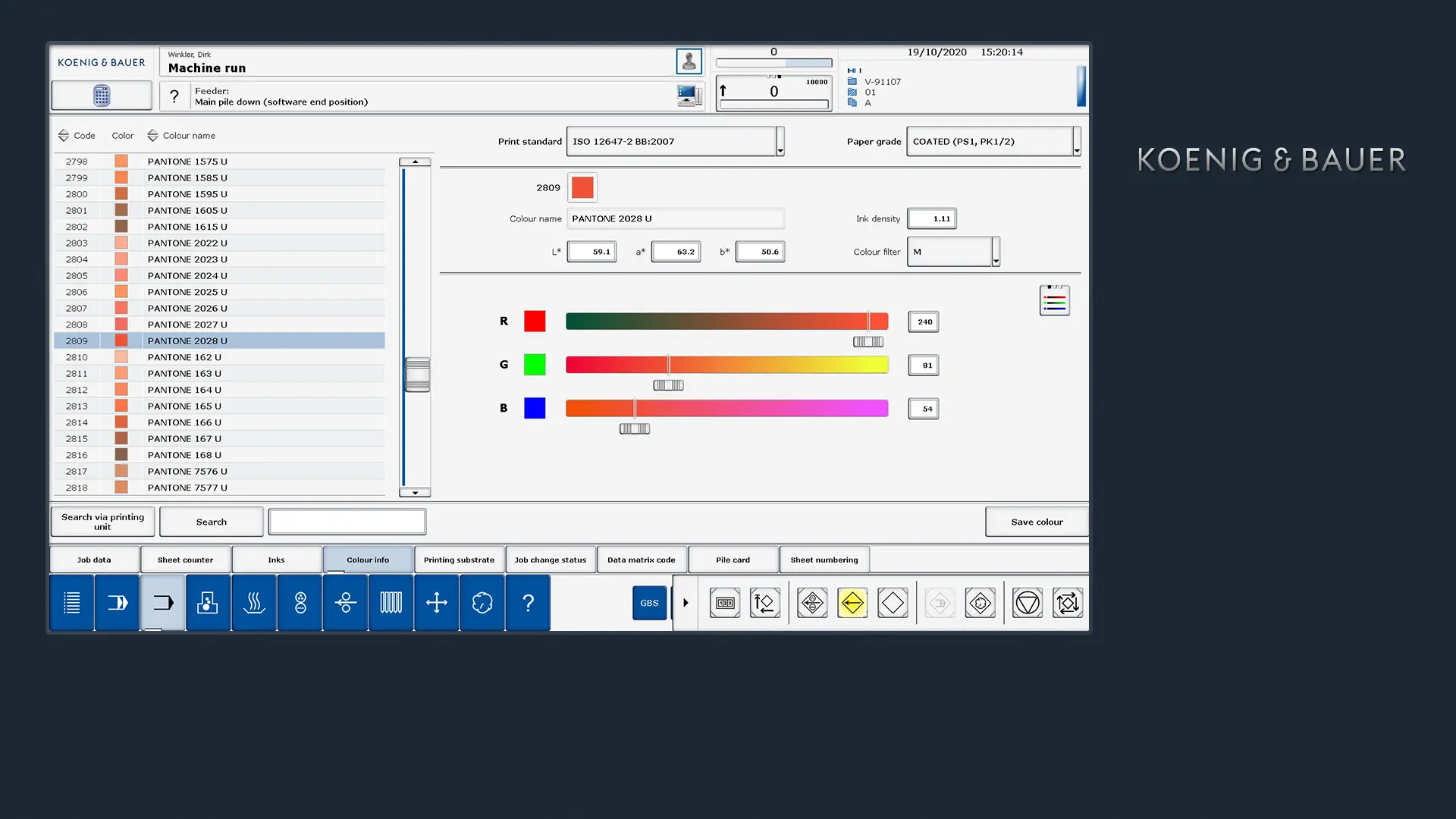

Colour Database with Extended Print and Colour Standards

Consistent colour quality, fast setup, and minimised colour corrections thanks to centralised management and adoption of CMYK and spot colour target values. Customised colour datasets based on paper and print standards reduce waste.

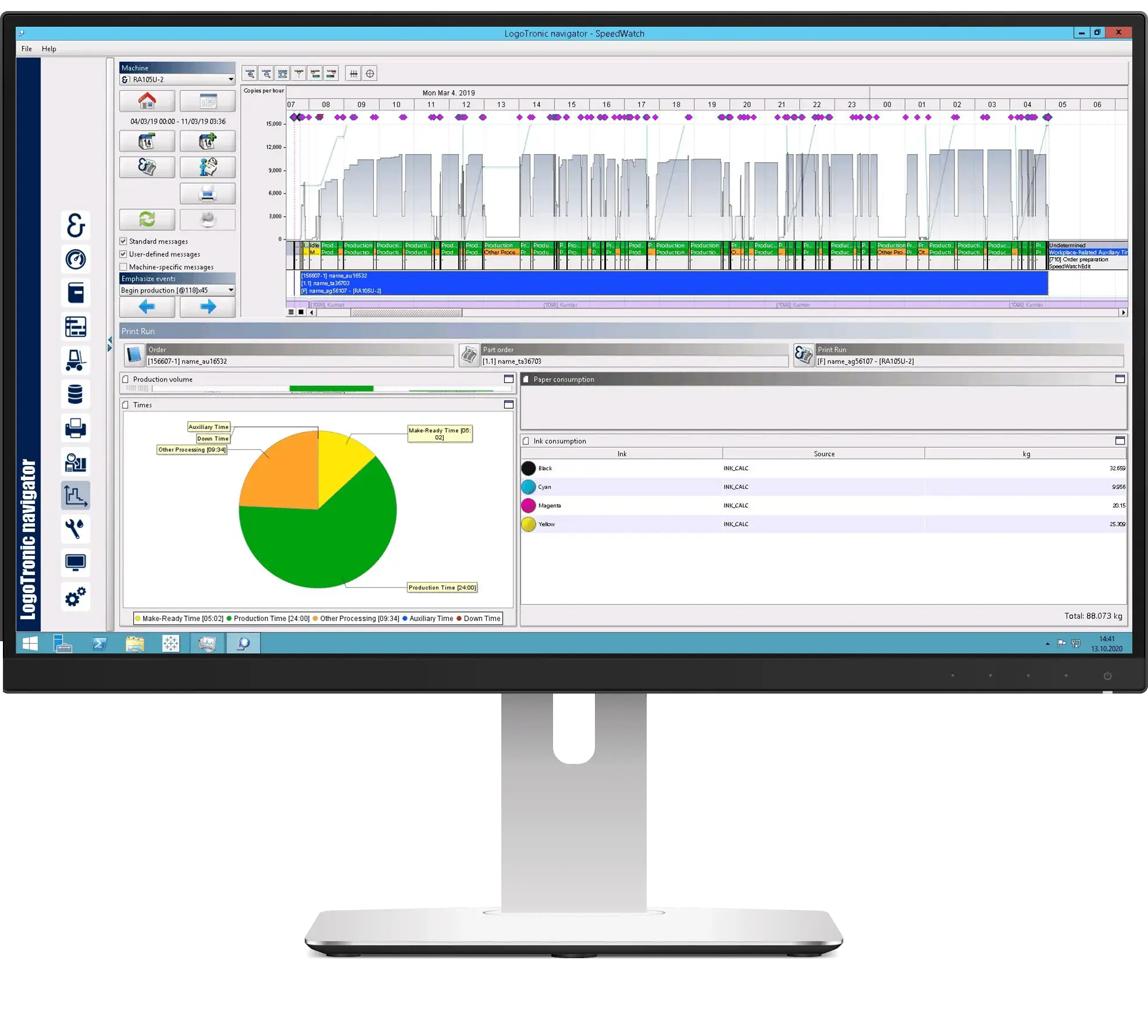

Integrate Third-Party Machines

LogoTronic BDE-Terminal & LogoLinkBox also integrate third-party machines: start/stop at the push of a button, automatic time tracking, and full transparency over every work step.

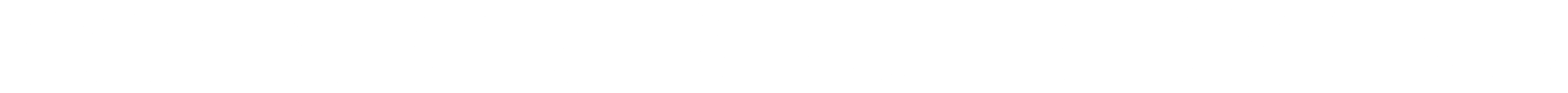

Production Data Acquisition

Automatic acquisition of all operational and machine data – the foundation for precise planning and Lean Management.

Quality Protocols

All quality protocols are directly linked to specific jobs – for quick access and efficient complaint processing.

Maintenance Manager

Automated planning of regular and preventive maintenance. Increased availability, clear documentation, and long-term preservation of your machines’ value.

Your advantages

Lower Set-up Costs, More Control

Thanks to intelligent automated processes, you’ll make your production more efficient – and maintain control at all times.

Sustainable Efficiency Improvements

Lean processes and reliable decision-making bases: pre- and post-calculations based on exact operational and machine data ensure increased cost-effectiveness.

Scalable & Flexibly Expandable

LogoTronic constantly adapts to your needs – new functions can be added at any time.

Minimise Complaint Costs

Productivity That Impresses – What Our Customers Say

"Twice as many orders with the same team. Fantastic! And now we know: there's even more potential!"

Wolfgang Silber, Managing Director, Druckerei Silber Druck oHG

"LogoTronic is the perfect link between management and production levels: it provides information to the printing machines for pre-setting and records operational data seamlessly and in real-time."

Christian Mergard, Production Manager, Druckerei Silber Druck oHG