Kyana Data

Decisions made simple.

Kyana Data is the intelligent production data analysis tool for full data transparency in print and packaging production.

With Kyana Data, you can easily create complex analyses and bring full transparency to your production processes. This enables you to achieve unimagined peak performance through well-founded, data-based decisions. Unleash the full power of data now! Unleash the full power of data now.

60 different key figures

Countless optimisation potentials

Unleash the full power of data now.

Why data transparency?

Data transparency is the key to optimised production for companies in the printing and packaging industry. Continuous monitoring, intuitive visualisation and detailed analysis of complex data enable fast and objective decision-making at all levels of the company. Recognising unusual patterns and anomalies in conjunction with the machine data also enables preventive maintenance measures to avoid machine downtime. Use the knowledge from your data to identify optimisation potential and significantly increase your production efficiency.

Features

In the digitalised world, data is the key to optimising production processes. Kyana Data makes it easy to understand this data and derive valuable insights.

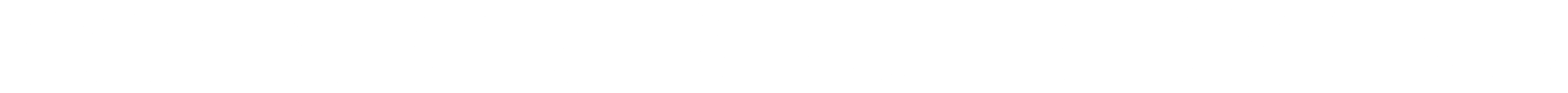

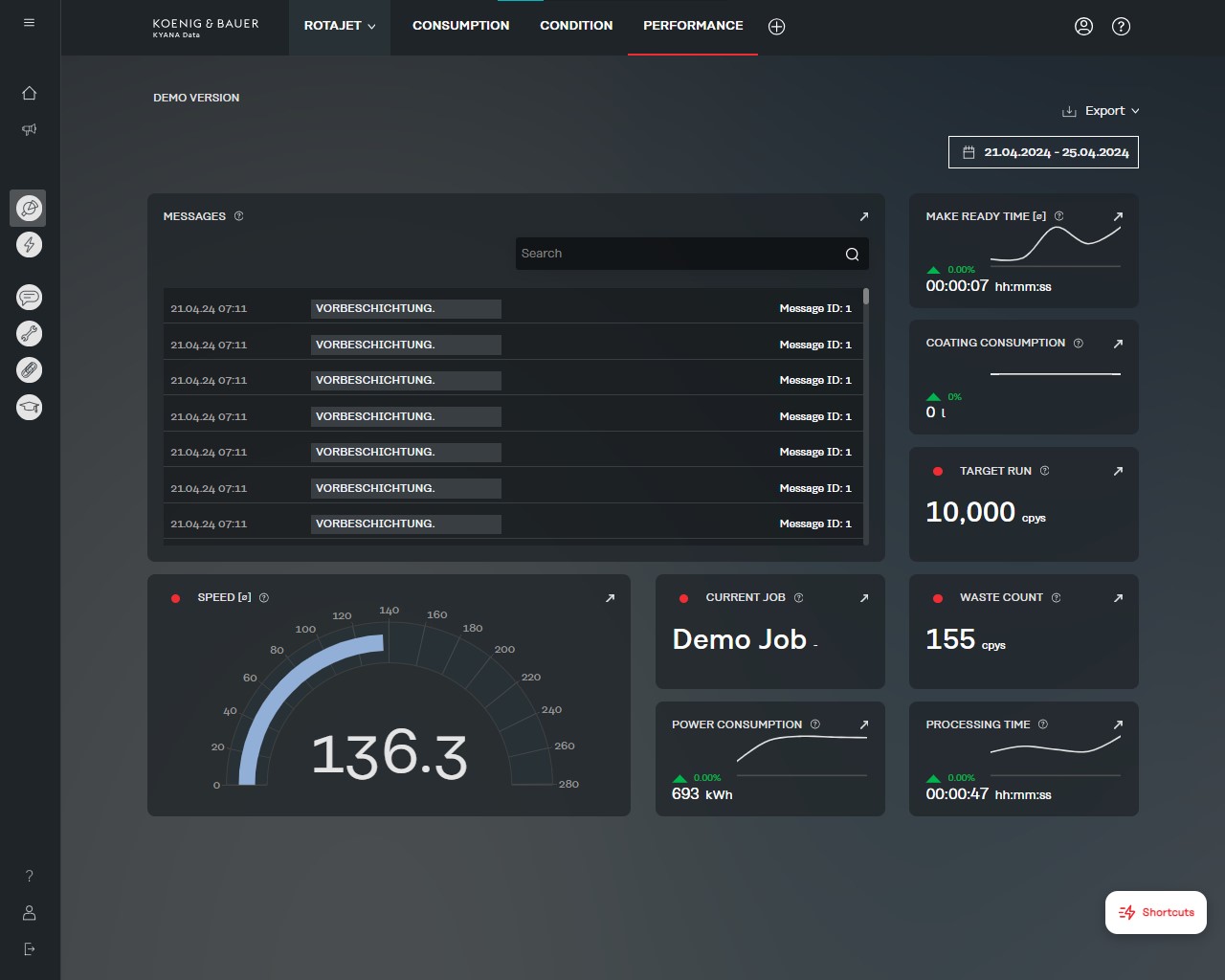

Freely configurable dashboards

Easily create meaningful analyses and gain full transparency of your production processes. Visualise and analyse production data based on relevant KPIs in flexible dashboards. Whether preconfigured standard dashboards or customised views – design your data analysis according to your needs.

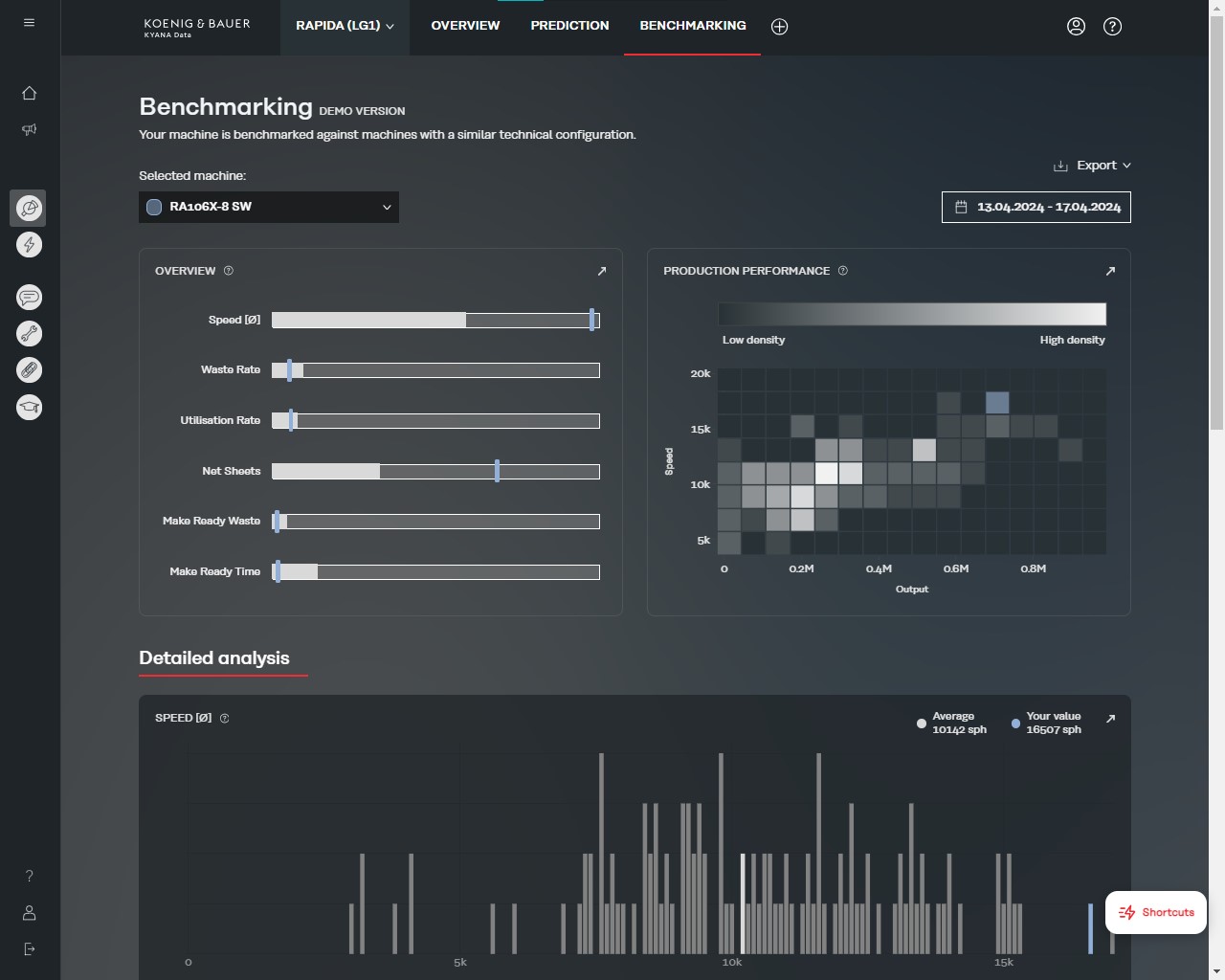

Real-time production monitoring

With Kyana Data, you can track the most important key figures of your production in real time. Live KPIs* allow you to continuously monitor machine performance, operating conditions and production processes. Proactively identify bottlenecks and problems to minimise downtime and increase your efficiency (*currently available for the RotaJET series).

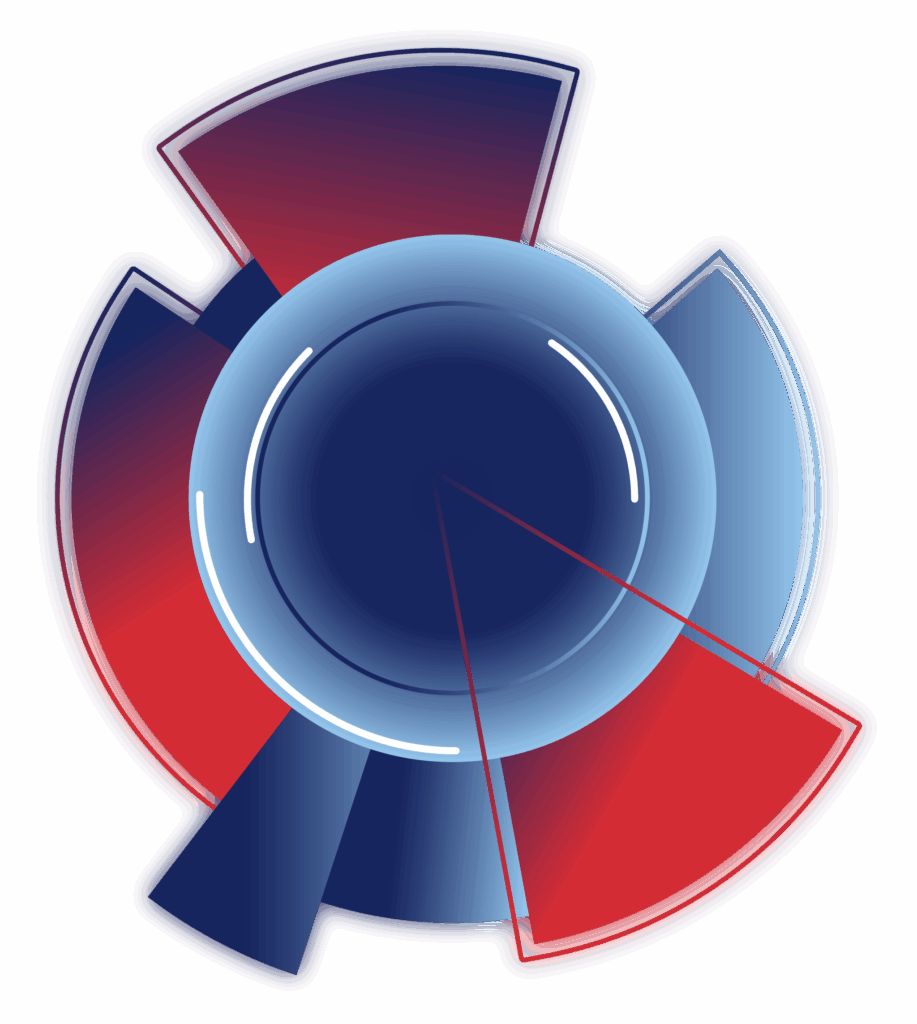

Preventive maintenance instructions

Kyana Data enables continuous monitoring of your systems. Intelligent prediction bots serve as an early warning system and inform you with graphical visualisations in clear dashboards when machine anomalies occur. This allows you to recognise problems at an early stage and proactively prevent machine damage and possible breakdowns.

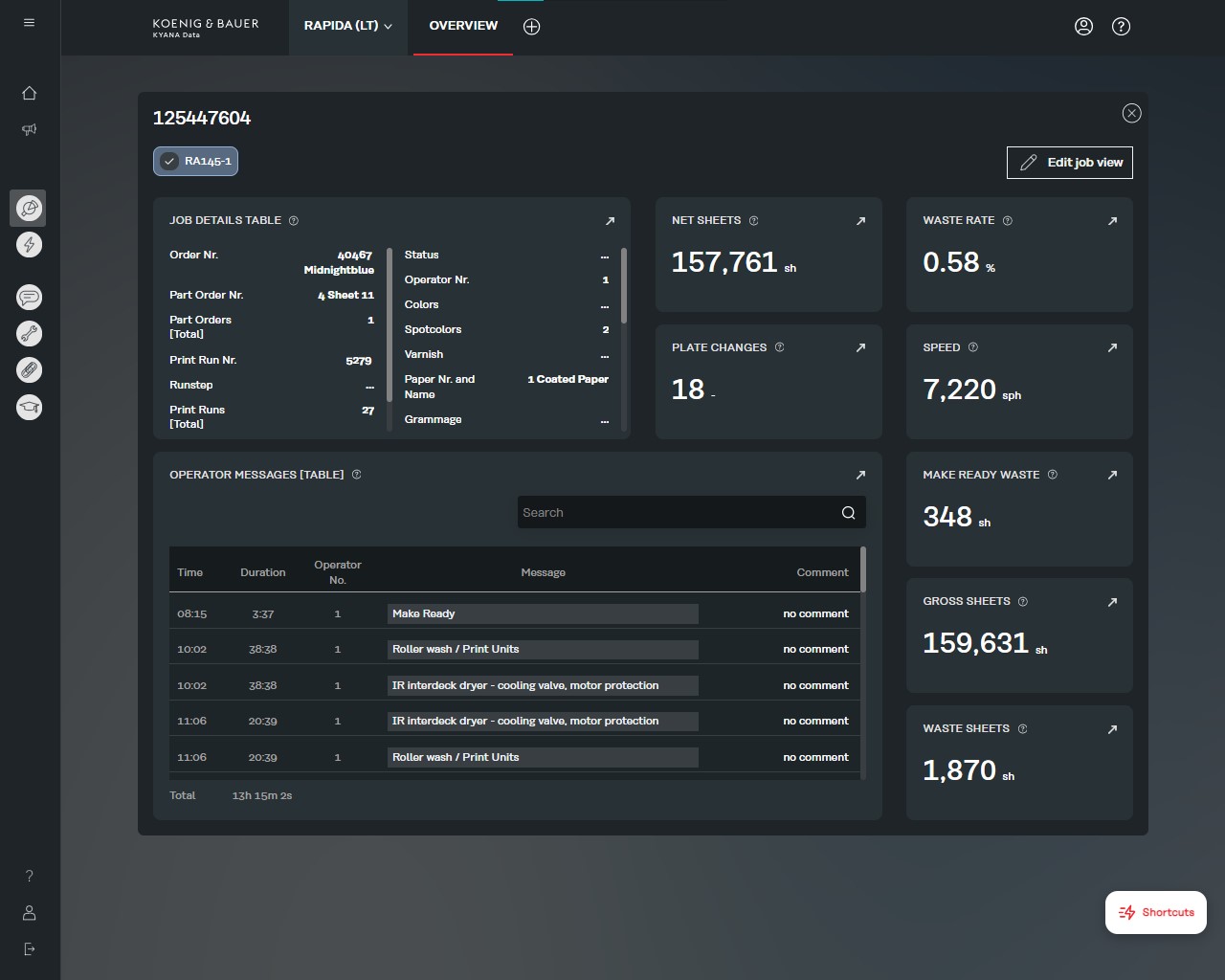

Intelligent benchmarking

With the benchmarking function, you can compare the KPIs of your machines with those of similarly equipped machines in an anonymized comparison group. Gain valuable insights into your competitive situation and identify potential improvements for your production. This will strengthen your market position in the long term.

Your benefits

Access from anywhere

The cloud-based software gives you access to your production data from anywhere in the world at any time – provided there is an internet connection.

Intuitive user interface

Thanks to the intuitive user interface, you can create individual analyses and dashboards that are optimally tailored to the needs of your company in no time at all.

Time saving

Faster analyses, faster well-founded decisions, faster optimisations – Kyana Data significantly accelerates the performance of complex data analyses.

Compatibility

The tool is currently optimised for Rapida sheetfed offset presses and digital web printing systems from the RotaJET series. It is also possible to connect other machine types (including third-party machines).

Flexible subscription

Subscriptions give you the greatest possible flexibility and cost transparency. You only ever pay for the KPIs and optional functionalities you choose.

Data security

The security of your sensitive production data is our top priority. The cloud infrastructure offers state-of-the-art security measures to protect your data.