Kyana Connect

Opening new dimensions.

Kyana Connect is the secure IIoT gateway between your machines and the Koenig & Bauer Cloud.

With the free Kyana Connect IIoT gateway, you can manage the connection of your machines to the Koenig & Bauer Cloud and create the technical infrastructure to fully utilise the data-based digital solutions from Koenig & Bauer. Connect your machines and become IIoT-ready!

0 security leaks

100% data power

Connect all machines and gain insights.

Why get IIoT ready?

Even in the age of digital transformation, decision-makers in industrial print and packaging production still face the challenge of not having direct access to their machine data. The digitalisation of manufacturing processes enables unprecedented transparency in production. The decisive factor for data access is the IIoT capability of your systems. Increase your productivity, reduce your costs and secure a clear competitive advantage by relying on the transformative power of the Industrial Internet of Things.

Features

With Kyana Connect, you can fully utilise the possibilities of Koenig & Bauer’s digital product world while retaining full control over your valuable data.

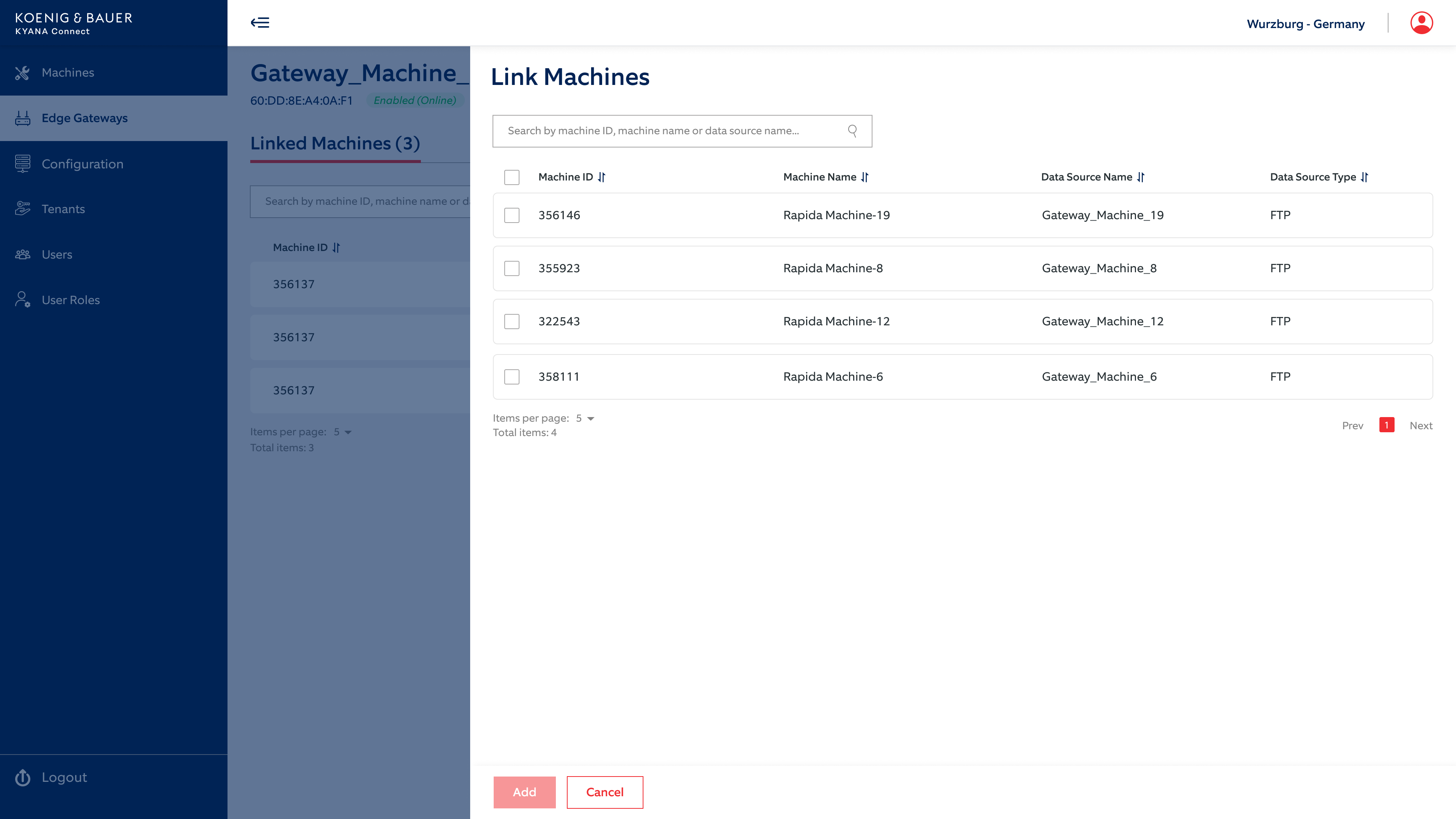

Seamless machine integration

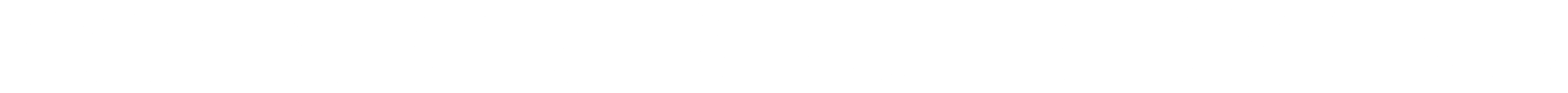

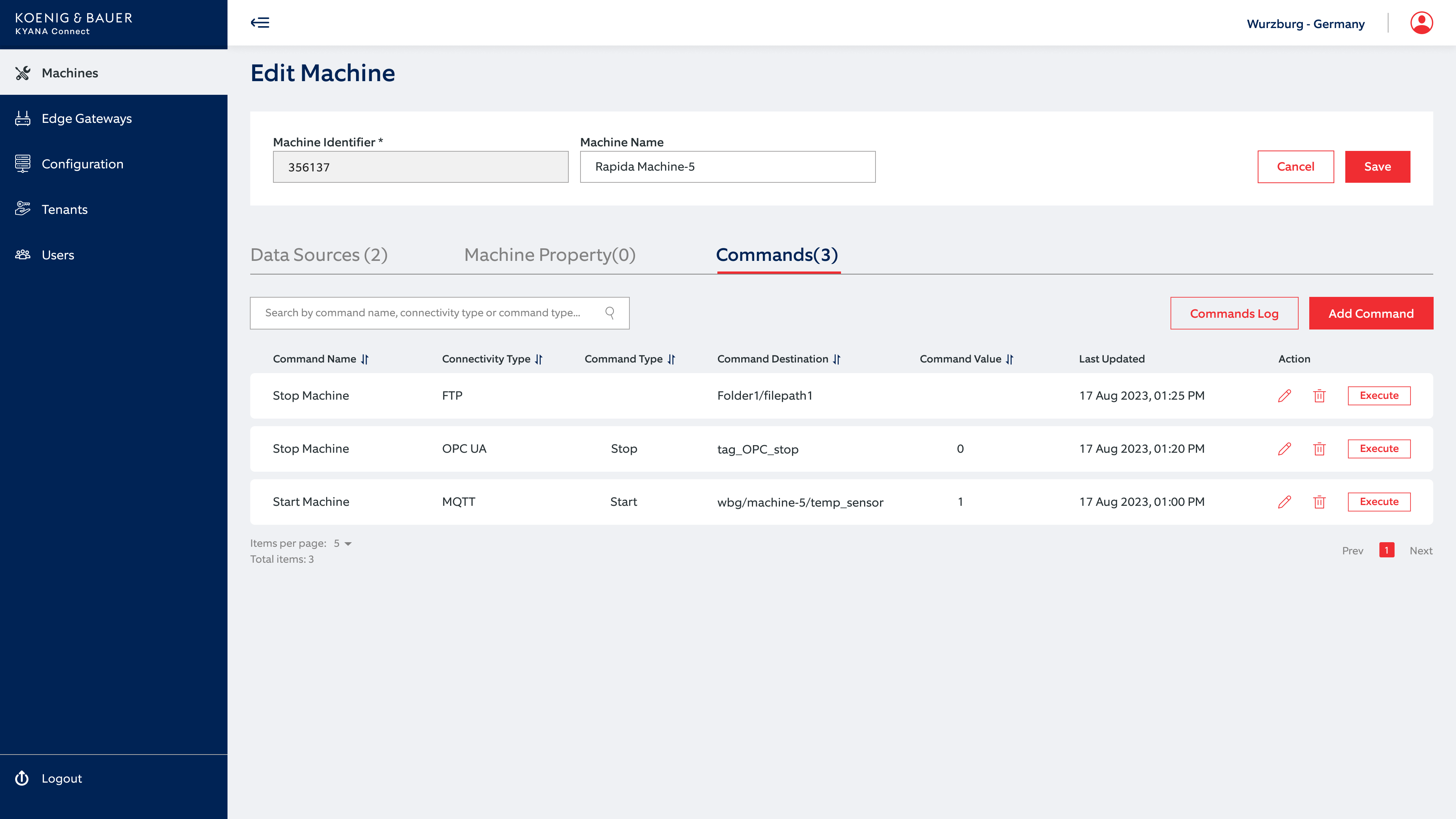

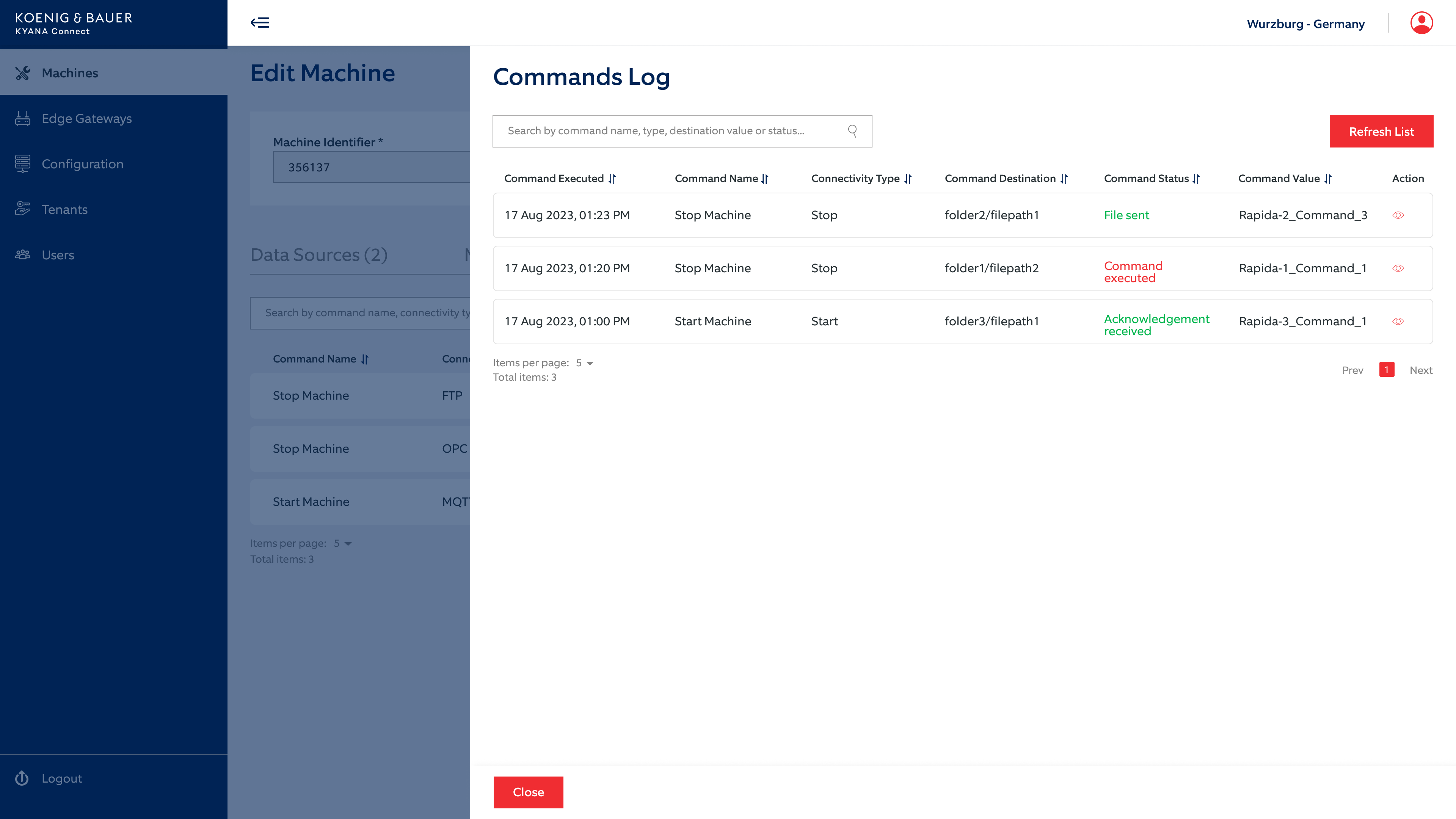

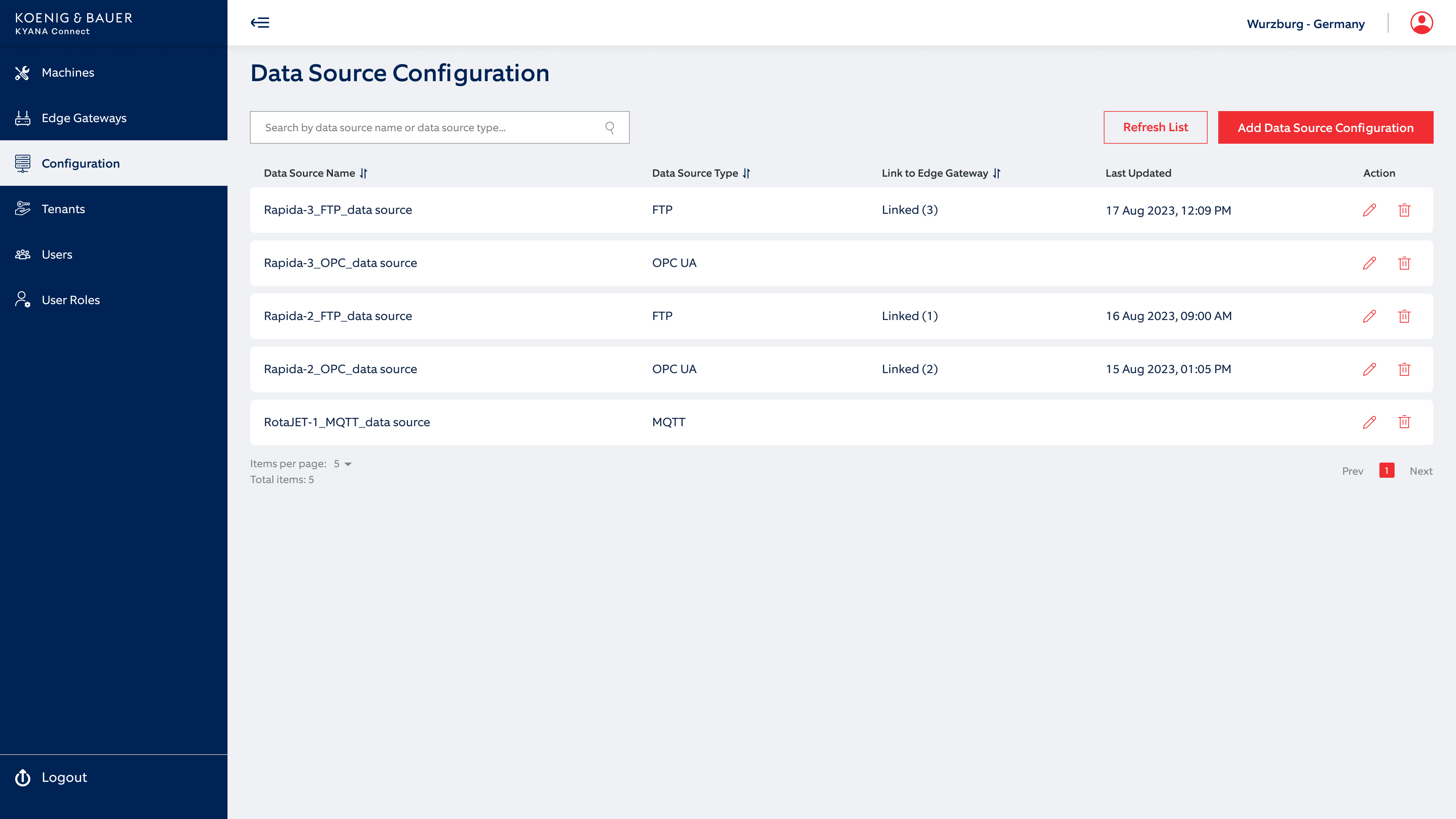

Kyana Connect ensures secure processing and transmission of machine, sensor and order data from your production to the Koenig & Bauer Cloud. The free software application supports a variety of protocols such as OPC UA or MQTT, which can be integrated as required.

Efficient edge computing

The edge device optimises data processing by pre-filtering the data close to the source, your production machine, at the edge of the network (“edge”) and only transmitting relevant data to the data centre in the required format – for fast processing that conserves computing resources and network bandwidth.

Full data transparency

Kyana Connect makes it possible to transfer the data generated by your Koenig & Bauer machines and devices to the Koenig & Bauer cloud, where it can also be made available in real time for further processing in dashboards or for machine status notifications.

IIoT capability

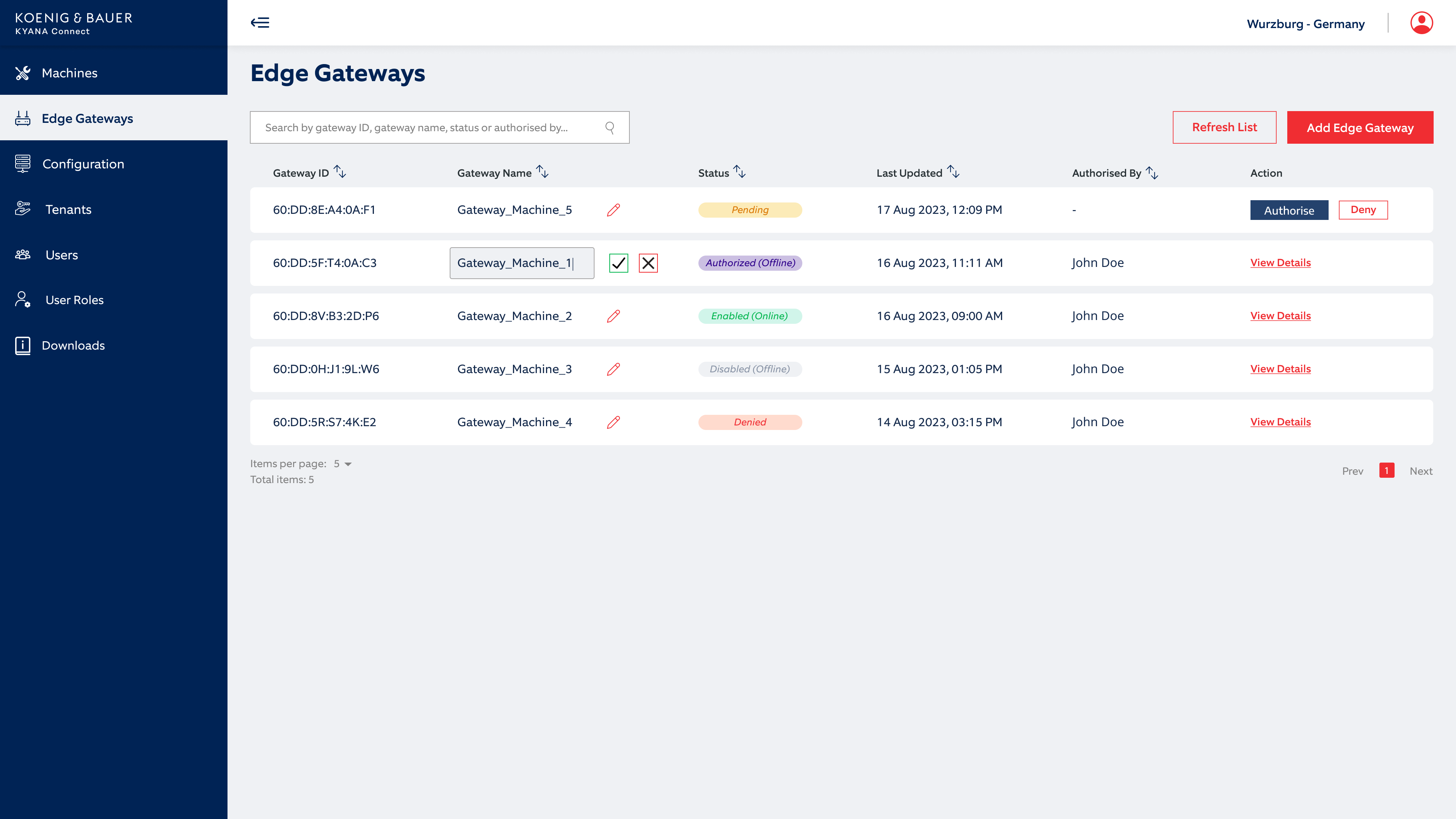

Kyana Connect is the technical foundation for the unrestricted use of all digital products associated with your Koenig & Bauer machine. Installation is essential for anyone wishing to carry out advanced data analysis. Your myKyana portal gives you a clear overview of the connected machines.

Your advantages

Data security

The security of your sensitive production data is our top priority. Kyana Connect is therefore regularly subject to security audits.

Free of charge

Installation of the software application is free of charge for all customers using data-based digital products from Koenig & Bauer’s digital product world.

Compatibility

The IIoT gateway can be integrated not only with new machines and devices, but in future also with your existing Koenig & Bauer equipment from older series.

Easy set-up

Your IT department can easily carry out the installation themselves. No production downtime is required either for the initial installation or subsequent updates.

Full data control

The configuration of data streams is in your hands. Data is only transferred from sources that your IT department has approved for transmission.