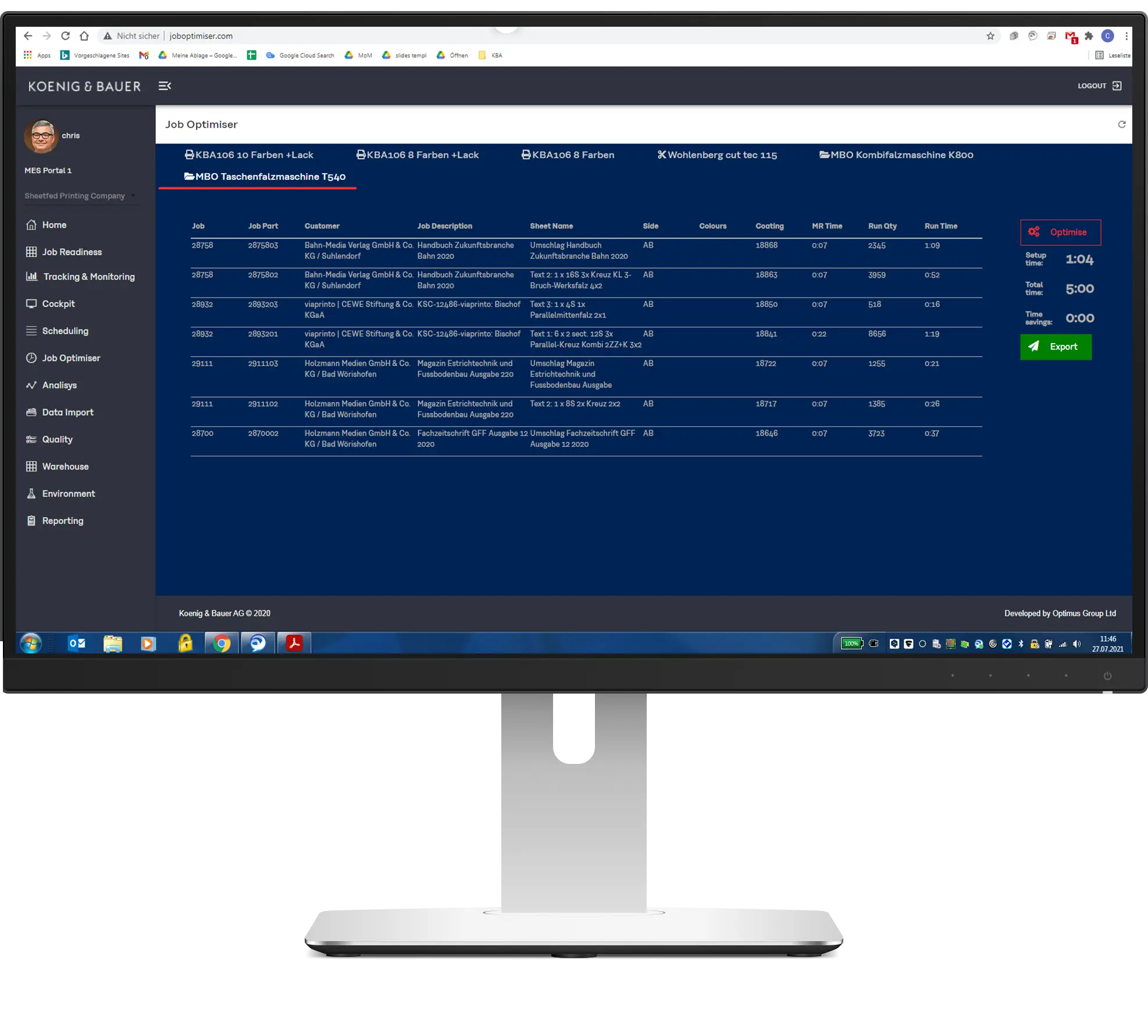

Job Optimiser

Your True Planning Advisor.

With the Job Optimiser, you can perfect your production planning down to the smallest detail – from the optimal job sequence to precise material provision. This saves you time, resources, and stress.

Reduce lead times

Increases machine productivity

More efficiency for your business

The Job Optimiser automates your detailed and capacity planning. Intelligent algorithms analyse job data, delivery dates, substrates, and finishing options to create the optimal production sequence. This allows you to save on setup times, avoid downtimes, and react flexibly to last-minute changes. Thanks to the Job Optimiser, materials such as printing plates, paper, and inks are available just-in-sequence. This reduces lead times and increases your machine productivity – for noticeably more efficient print production.

Features

Import of Pre-planning Data

Automatic import of all pre-planned production jobs from the MIS to ensure that all relevant job information is quickly available.

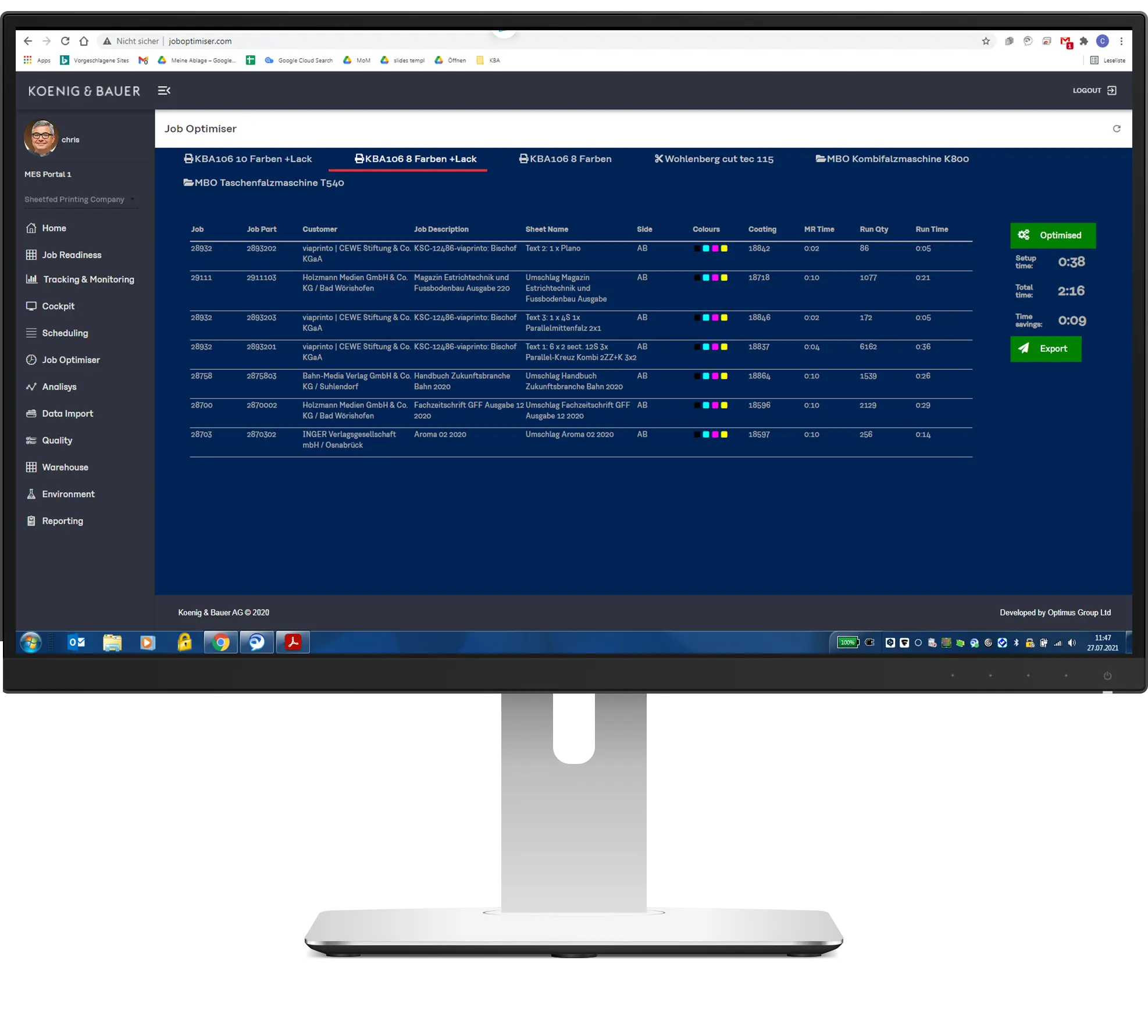

Intelligent Job Overview

Always keep an eye on the current production status: thanks to a clear job view with a traffic light assistant. This allows you to immediately see whether all materials, tools, proofs, and approvals are available.

Machine Occupancy Planning with Load Balancing

Thanks to intelligent load balancing, operations are automatically distributed to suitable printing and finishing machines to optimally utilise machine resources.

Convenient Quick Filter Function

With just a few clicks, you can filter out all production-ready jobs and transfer them directly to detailed planning.

Dynamic Resource Planning

Intelligent control algorithms automatically adjust the load distribution – depending on job parameters, automation level, and capacities. This ensures your detailed planning remains reliable, even with last-minute changes.

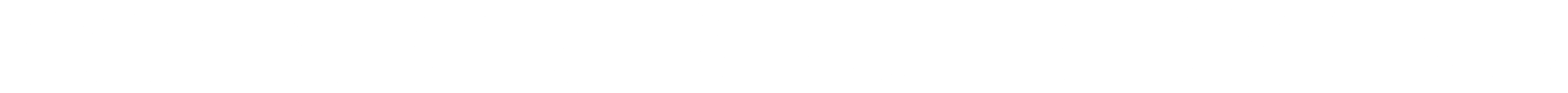

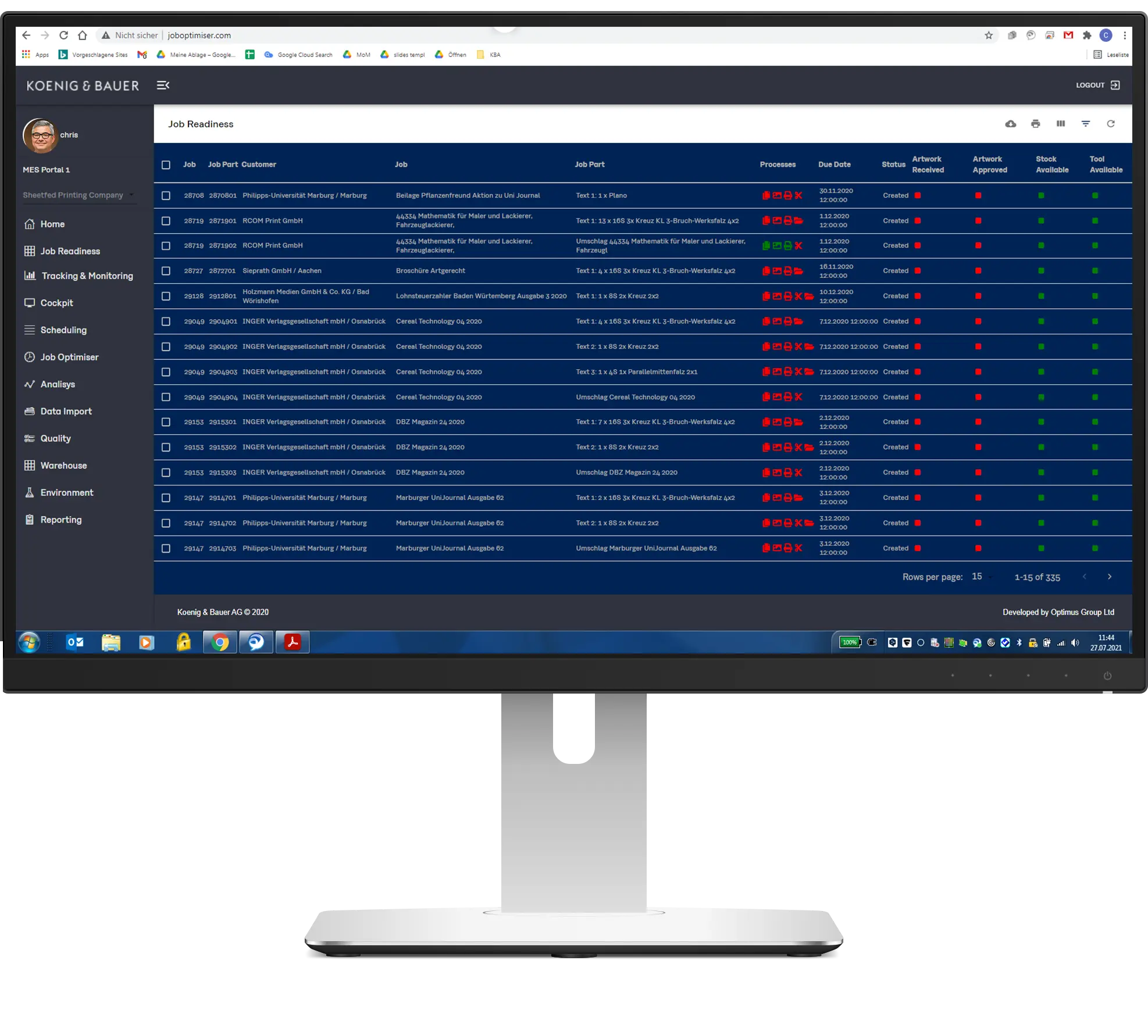

Optimised Sequence Planning

The automatic sequencing of jobs minimises your setup times. Print and machine-specific parameters such as varnish type or automation level are always taken into account. Planning changes? No problem – re-planning and setup time adjustments happen automatically. And for perfect process synchronisation, the optimised list is transferred directly to LogoTronic.

Your benefits

Unbeatable Efficiency Increase

Reduced planning effort, minimal lead times: this sustainably increases your productivity and secures you a clear competitive advantage.

Less Downtime, Lower Setup Costs

Thanks to optimally planned production sequences, machines are used with maximum efficiency, thus reducing your unplanned expenses.

Optimised Resource Planning

Intelligent material requirements planning minimises your storage costs and guarantees the on-time completion of all products.

Real Planning Security –

Our Customers Are Delighted!

"Jobs with less than 24 hours lead time are now truly profitable – with perfect production planning!"

Wolfgang Silber, Managing Director, Druckerei Silber Druck oHG