Digital Products

Digital technologies have the potential to revolutionise the way print products are designed, manufactured and experienced. Competent data handling and intelligent process automation in a seamless end-to-end workflow make print and packaging manufacturers faster, more flexible and more efficient. With data-based tools and artificial intelligence, they take your production to a new level of performance.

Become an innovation champion!

Overview

Applied filters

VisuEnergy X

VisuEnergy X is the cutting-edge energy management system for a more climate-friendly printing and packaging industry. Protect the environment and reduce your production costs with the ISO 50001-certified energy management system (EnMS) for energy-efficient printing and packaging production.

LogoTronic

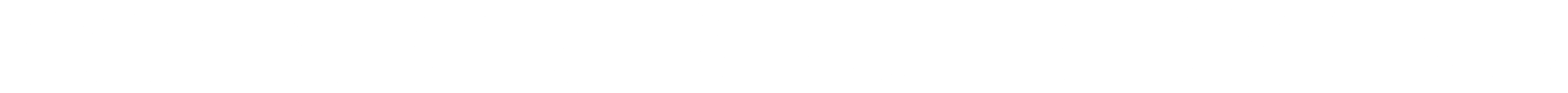

LogoTronic is the data hub of your production and the perfect link between the management and production levels: it supplies presetting data to the presses, seamlessly records operating data and provides you with reliable production data and analyses. Network your production and increase your productivity many times over.

The IIoT gateway for seamless machine connectivity

KYANA Connect

The application ensures secure processing and transfer of your production data to the Koenig & Bauer Cloud. This creates the technical prerequisites for the full use of data-based digital solutions from Koenig & Bauer and opens up new dimensions in data analysis.