About us

Koenig & Bauer Kyana

By harnessing the transformative power of digital technologies, we challenge the status quo and open up a universe of new possibilities for the print and packaging industry.

We develop digital solutions and data-driven business models for and with our customers along the entire lifecycle of print products – from the initial idea to market maturity. This is how we take the great machines from Koenig & Bauer to the next level and enable users to work with them faster, better and more efficiently.

Tradition meets digital innovation

The corporate startup becomes Koenig & Bauer Kyana

We are the digital pioneers at Koenig & Bauer. We are expanding Koenig & Bauer’s traditional core business, printing and post-press technology, to include digital solutions with real added value.

By combining in-depth expertise with the latest technologies, state-of-the-art tools and agile development methods, we support the implementation and distribution of scalable digital solutions across all substrates and print applications in close cooperation with the Group’s various business units. For a future-proof Koenig & Bauer and a future-proof industry.

Digital business areas

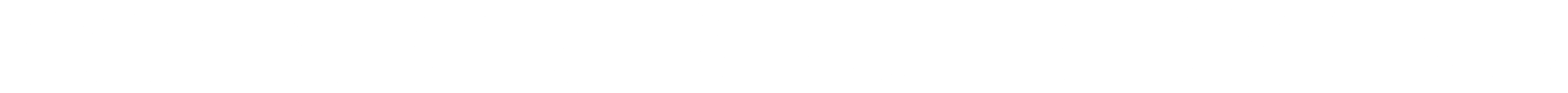

Digital technologies have the potential to revolutionise the way print products are designed, produced and experienced.

From real-time data analysis in production and augmented reality in remote maintenance to artificial intelligence for proactive optimization suggestions to operating personnel – print shops in which digital technologies set the pace work more efficiently, productively and resource-efficiently. Today, the path to maximum productivity and competitiveness for printing and packaging companies is inextricably linked to end-to-end automated workflows and the competent use of digital tools.

Get to know us

Leadership Team

Marcel Guntsch

"As a bridge between digital innovation and traditional machine manufacturing, we rely on the best of both worlds, using the process engineering know-how of the entire Group as well as agile software development methods to offer our customers innovative solutions tailored to their needs."

Sandra Wagner

"For us, digitalization is an essential part of our corporate strategy and the basis for a successful future for the entire industry. With innovative technologies and new business models, we ensure the competitiveness of our customers and offer clear added value."

Dr. Felix Oberdorf

"To create unique solutions, we use the latest technologies and findings from data science and user interface design. We continuously incorporate feedback from our users into the development process."

Interdisciplinary team

Our multi-disciplinary team is made up of passionate strategists, product owners, scrum masters, UI/UX designers, data scientists, developers and community management, sales and marketing experts who share a common vision: Together we are leading the printing and packaging world into the digital future.